Dosificador de sólidos y polvos

Dosificador de sólidos y polvos

una bomba programable, única para sustancias sólidas sólidas en polvo de flujo libre

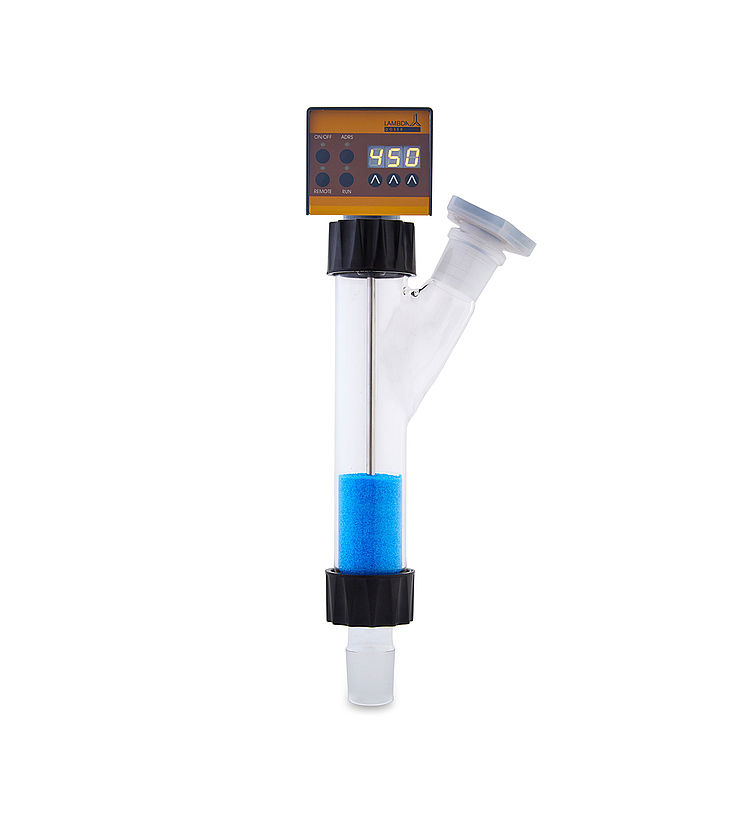

El LAMBDA DOSER es una bomba programable, única para sustancias sólidas sólidas en polvo de flujo libre. El dosificador permite la adición automática o continua de substancias en polvo, substancias polvorosas y cristalinas, sin necesidad de cucharilla o espátulas.

El dosificador DOSER consiste en una unidad de dosificación acoplada a un motor paso a paso controlado digitalmente por una moderna electrónica. La bomba dosificadora permite una adición constante y reproducible, incluso de sustancias en polvo “difíciles” de manipular.

El dosificador de sólidos DOSER ofrece diferentes posibilidades de control remoto o a distancia y puede ser utilizado para el control automático de una gran variedad de procesos.

El LAMBDA DOSER modernizará su laboratorio.

Galería de imágenes del dispensador de polvo:

Los instrumentos de dosificación de polvo como DOSER 0.2 L, DOSER 1 L, DOSER 3 L, HI-DOSER 1 L, HI-DOSER 3 L y sus accesorios y consumibles se pueden ver en https://www.lambda-instruments.com/es/dosificador-de-solidos/doser-hidoser-galeria/

Características del dosificador de sólidos LAMBDA DOSER

Caudal

El control digital de la velocidad de dosificación de 0 a 999 permite la dosificación de sólidos de forma precisa y reproducible (por ejemplo: 50 mg/min hasta 50 g/min para el NaCl).

Programable

Se pueden programar fácilmente hasta 27 pares de velocidades y tiempos de dosificación.

Capacidad

El recipiente de vidrio tiene una capacidad de aproximadamente 200 mL (equivale a 250 g de NaCl, 200 g de NaHCO3, 150 g de sacarosa). Esta capacidad es ideal para la mayoría de las aplicaciones en el laboratorio. También suministramos un recipiente de 1 L aproximadamente.

Seguridad

Gracias al DOSER, la adición de sustancias químicas pulverulentas ha pasado a ser reproducible, segura y conforme a las normas de seguridad y estándares de calidad para la manipulación de productos químicos en el trabajo de investigación en el laboratorio (GLP). Su construcción hermética permite la manipulación segura de sustancias sólidas peligrosas o tóxicas.

Fácil montaje y limpieza

El dosificador de sustancias en polvo LAMBDA DOSER ha sido construido persiguiendo su fácil ensamblaje y limpieza. Puede ser conectado a cualquier recipiente de vidrio provisto de una conexión con esmerilado normalizado NS 29/32 o conexión con rosca SVL. Todas las partes que entrarán en contacto con las sustancias en polvo están hechas de materiales químico-resistentes.

Pequeñas dimensiones y robusta construcción

Se ha puesto especial atención en la creación de una bomba de pequeñas dimensiones, en consecuencia, el dosificador LAMBDA DOSER. El DOSER puede ser fácilmente adaptado a instalaciones de laboratorio complejas. Su robusta construcción y la alta calidad de sus materiales aseguran la larga vida útil de la bomba para sustancias en polvo LAMBDA DOSER.

Atmósferas controladas

Varios cierres herméticos permiten que el DOSER pueda ser utilizado bajo una leve sobrepresión o vacío. Así, si un proceso lo requiere, el DOSER puede ser lavado con un gas inerte durante la dosificación.

Económico

El usuario podrá ocuparse en otras labores, ya que el DOSER, por su sistema de adición automática de sustancias sólidas, permite la disminución en el número de experimentos, asegura la reproducibilidad del caudal y evita la repetición de experimentos a causa de errores de manipulación. Además, el dosificador de sustancias sólidas en polvo DOSER ofrece una excelente relación calidad-precio.

Control a distancia / control remoto

La velocidad de adición puede ser controlada a distancia en un intervalo completo mediante la aplicación de una tensión o voltaje de 0-10 V. La señal de encendido y apagado (ON/OFF) se efectúa por un simple contacto externo o por una señal de 12V. La interfaz RS-485 o RS-232 (opcional) permite el control avanzado por computador (caudales variables, gradientes de dosificación, etc.). Un programa de control PNet (opcional) también está disponible.

Cuantificación de las sustancias dosificadas

El DOSER puede ser configurado con el integrador electrónico LAMBDA INTEGRATOR (opcional) que permite determinar la cantidad de sustancia agregada en función del tiempo. Estos datos brindan información muy importante sobre el proceso y las reacciones, por ejemplo, cuando el dosificador es controlado, por un pH-stat (o pHmetro), termóstato, etc.

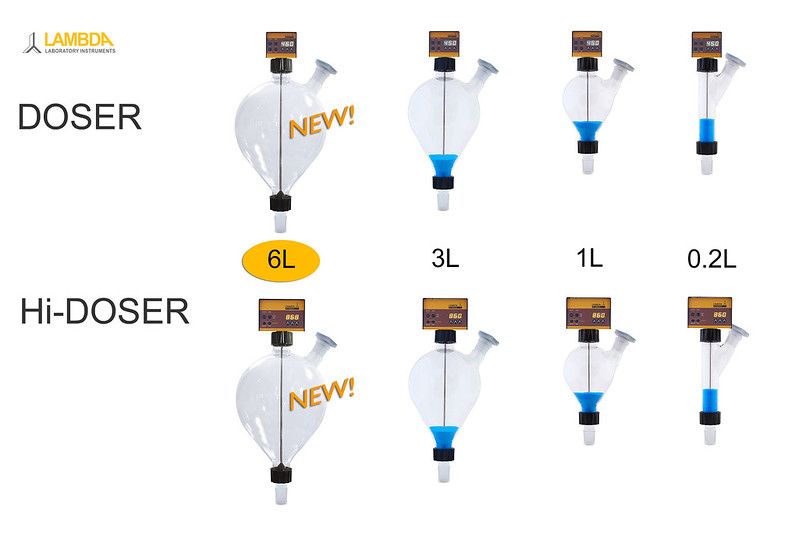

Programación: DOSER: Hasta 27 pasos de velocidad de flujo o caudal y tiempo; HI-DOSER: Hasta 99 pasos de velocidad de flujo o caudal y tiempo

Tiempo de resolución: 0 hasta 999 minutos en pasos de 1 minuto o de 0 hasta 99.9 minutos en pasos de 0.1 minuto: el tiempo de resolución puede ser seleccionado individualmente para cada paso de programa

Motor: DOSER: Motor a pasos controlado por microprocesador; HI-DOSER: Motor de imanes permanentes sincrónicos BLDC (magnetos de neodiminio) controlado por microprocesador

Intervalo de control de velocidad: 0 hasta 999

Interfaz: RS-485 o RS-232

Fuente de energía: DOSER: 95–240 V/60–50 Hz CA conector a fuente de energía con salida a CD 12V/12W; HI-DOSER: 95–240 V/60–50 Hz CA conector a fuente de energía con salida a CD 12V/50W; Posibilidad de operación en campo con el uso de una batería de 12 V

Volumen: Aprox. Vasos de vidrio de 0.2 l, 1 l y 3 l

Dimensiones: DOSER Unidad del Motor: 6 (H) x 7 (A) x 13 (P) cm; HI-DOSER: Unidad del Motor: 10.5 (A) x 9.5 (H) x 13 (P) cm; Vaso de vidrio 0.2 l: 30 (H) x12 (A) x 5 (P) cm; Vaso de vidrio 1 l: 30 (H) x 18 (A) x 14 (P) cm; Vaso de vidrio 3 l: 38 (H) x 21 (A) x 17.5 (P) cm;

Seguridad: Conforme a la CE, conforme con la norma IEC 1010/1 para instrumentos de laboratorio

Temperatura de operación: 0 - 40 °C

Humedad de operación: 0-90% HR, sin condensado

Control remoto: 0-10 V (Control de velocidad de dosificado); 3-12 V CD (control ON/OFF); opción 0-20 o 4-20 mA; con interruptor de pie

Software: Programa de control por computador PNet (opcional)

- DE - Pulverdosiergerät LAMBDA DOSER und HI-DOSER - Prospekt (pdf)

- DE - Bedienungsanleitung - LAMBDA DOSER Pulverdosiergerät (pdf)

- ES - Dosificador de solidos LAMBDA DOSER / HI-DOSER (pdf)

- ES - Instrucciones de uso - Dosificadora de sólidos y sustancias pulverulentas LAMBDA DOSER (pdf)

- RU - Дозаторы порошков LAMBDA DOSER и HI-DOSER - Листовка (pdf)

- RU - Руководство по эксплуатации - Дозаторы порошка LAMBDA DOSER и HI-DOSER (pdf)

- FR - Mode d'emploi - LAMBDA DOSER doseur de poudres programmable (pdf)

- FR - LAMBDA DOSER / HI-DOSER doseur de poudres programmable - brochure (pdf)

- CZ - Návod k obsluze - Dávkovač pevných, krystalických látek a prášků LAMBDA DOSER (pdf)

- CZ - Automatický dávkovač pevných, krystalických látek a prášků LAMBDA DOSER (pdf)

- EN - LAMBDA DOSER and HI-DOSER powder dosing instrument - Leaflet (pdf)

- EN - Operation manual - LAMBDA DOSER and HI-DOSER powder dosing instrument (pdf)

- EN - Application note - LAMBDA powder DOSER - Reproducible powder dosing (pdf)

2024

El sólido de sílice húmeda tratado térmicamente se se añadió al reactor con el dosificador de sólidos LAMBDA DOSER

Luo, L., Rix, F. C., Stevens, K. A., Kuo, C. L., Zhang, X., Lovell, J. A., Harlan, C.J., Ye, X., & Berg, B. R. (2024). Improved In-Situ MAO Derived Silica Supported Single-Site Metallocene Catalysts. U.S. Patent Application No. 18/253,867.

https://patents.google.com/patent/US20240092947A1/en (17 de junio de 2024)

Para los experimentos de "pirólisis flash", la biomasa en polvo (mezcla de celulosa, hemicelulosa, lignina y cenizas) se introdujo en la línea de nitrógeno dentro de un venturi utilizando un "alimentador de polvo" LAMBDA Hi-DOSER a una tasa entre 1 y 20 g/mn.

Proust, C., Proust, M., & Foyer, J. (2024, February). High temperature pyrolysis of lignocellulosic biomass for biogas production. In Technological Systems, Sustainability and Safety.

https://hal.science/hal-04538203 (2024 May 14)

Estudios de segregación de sólidos: El dispensador de sólidos LAMBDA DOSER 3L dosifica sólidos continuos a una velocidad de hasta 13.7 g/min en la parte superior del reactor de lecho fluidizado.

Ciércoles, R., Lasobras, J., Soler, J., Herguido, J., & Menéndez, M. (2024). A Preliminary Assessment of Sorption Enhanced Methanol Synthesis in a Fluidized Bed Reactor with Selective Addition/Removal of the Sorbent. Removal of the Sorbent.

https://dx.doi.org/10.2139/ssrn.4735903

Antes de comenzar la pirólisis, se mezclaron uniformemente 6 g de materiales y se agregaron al alimentador LAMBDA DOSER 0.2L

Wang, X., Peng, Y., Zhou, R., Fan, L., Zhang, Q., Cui, X., Wu, Q., Zeng, W., Tian, X., Ke, L., Ruan, R., & Wang, Y. (2024). Production of monocyclic aromatic hydrocarbons from microwave co-pyrolysis of polyethylene terephthalate and low-density polyethylene using coconut husk carbon as microwave absorbent. Chemical Engineering Journal, 150732.

https://doi.org/10.1016/j.cej.2024.150732

Estudio sobre la importancia de las características de la materia prima (humedad, materia volátil, carbono fijo y contenido de cenizas) durante la etapa de alimentación de partículas para la gasificación por corriente descendente de residuos de biomasa: se utilizó un equipo de dosificación de polvo Lambda (LAMBDA DOSER 0.2 L) para la alimentación de partículas (residuos de palma datilera, orujo de aceituna, lodos de depuradora). Se probaron el caudal del gasificador, la potencia nominal y el tiempo de almacenamiento.

Khan, S., Adeyemi, I., Moustakas, K., & Janajreh, I. (2024). Investigating the characteristics of biomass wastes via particle feeder in downdraft gasifier. Environmental Research, 118597.

https://doi.org/10.1016/j.envres.2024.118597

2023

El equipo de dosificación automático LAMBDA DOSER se utilizó para alimentar de forma continua entre el 70 % y el 80 % de Al2O3 requerido para una eficiencia de corriente teórica del 100 %. Los límites del sistema se alcanzaron en algunos casos después de 6 a 10 h debido a una obstrucción crítica en el canal de alimentación de alúmina.

Singh, K., Gunnarsson, G., Magnusson, J. H., Haarberg, G. M., & Saevarsdottir, G. (2023). Performance Evaluation of Low-Temperature KF-NaF-AlF3 Electrolytes for Aluminum Electrolysis Using Vertical Inert Cu–Ni–Fe Alloy Anodes. Journal of The Electrochemical Society, 170(11), 113507.

https://doi.org/10.1149/1945-7111/ad0bae

Batería de iones de litio: Alimentación de polvo precursor (Silicio y ferroceno [Fe(C5H5)2]; 1 g/min) en una columna de plasma de onda superficial sostenida (SWS) (temperatura del núcleo >4000 K)

Jie, Z., Zhang, Z., Bai, X., Ma, W., Zhao, X., Chen, Q. & Zhang, G. (2023). Surface-wave-sustained plasma synthesis of graphene@Fe–Si nanoparticles for lithium-ion battery anodes. Appl. Phys. Lett. 11 September 2023; 123 (11): 113902.

https://doi.org/10.1063/5.0159269

2022

La muestra de granulado de HDPE se colocó en el dosificador (LAMBDA DOSER 1 L)

Dai, L., Zhou, N., Lv, Y., Cobb, K., Chen, P., Wang, Y., Liu, Y., Zou, R., Lei, H., Mohamed, B. A., Ruan, R., & Cheng, Y. (2022). Catalytic reforming of polyethylene pyrolysis vapors to naphtha range hydrocarbons with low aromatic content over a high silica ZSM-5 zeolite. Science of The Total Environment, 847, 157658.

https://doi.org/10.1016/j.scitotenv.2022.157658

Canal experimental para la separación de partículas magnéticas: en el primer paso, las cenizas volantes se dosificaron mediante un sistema de dosificación LAMBDA con un recipiente de 1 litro (montado sobre una bandeja en el medio de la sección transversal del canal) en el canal horizontal y se dispersaron mediante aire comprimido (3 bar) que fluye desde una boquilla plana hacia la bandeja (ver Figura 1 de la publicación).

Czech, T. (2022). Morphology and chemical composition of magnetic particles separated from coal fly ash. Materials, 15(2), 528.

https://doi.org/10.3390/ma15020528

Dosificación de polvo de Al2O3 y otras partículas secas tamizadas en un generador de aerosol de circuito cerrado: Las partículas se dosificaron con un dosificador volumétrico de polvo LAMBDA DOSER 0.2L en una pieza en T de 1⁄4” donde el polvo fue recogido por una corriente de aire comprimido (5 L/min) y guiado como aerosol a través del chorro de la instalación.

Prüfert, C., Beitz, T., Reich, O. & Löhmannsröben, H.-G. (2022). Inline process analysis of copper-bearing aerosols using laser-induced breakdown spectroscopy, laser-induced incandescence and optical imaging. Spectrochimica Acta Part B: Atomic Spectroscopy 197 (2022) 106527.

https://doi.org/10.1016/j.sab.2022.106527

Las partículas de carbón se introdujeron en el reactor con la bomba de polvo programable controlado por microprocesador LAMBDA Hi-DOSER situado encima del tubo del reactor y purgado con N2. La ventaja de este alimentador de polvo es que la cantidad de alimentación es relativamente uniforme, lo que evita la obstrucción del alimentador y la inestabilidad de la producción de gas.

Dai, T., Xu, C., Zhang, Q., Liu, X., Chang, Z. & Yang, Y. (2022). Experimental study of the solar-driven steam gasification of coal in an improved updraft combined drop-tube and fixed-bed reactor. Energy Conversion and Management, Volume 259,2022,115571,ISSN 0196-8904.

https://doi.org/10.1016/j.enconman.2022.115571

El calor de disolución integral de la neutralización ácido-base se midió en un reactor agitado utilizando un calorímetro de reacción (RC1e, Mettler Toledo Ltd.) mientras el LAMBDA DOSER alimentaba continuamente ácido o base como sólidos: 23.6 g/min ácido cítrico; 30 g/min NaOH; 21 g/min NaOH; 14.8 g/min NaOH; 7.2 g/min NaOH

Ran, Z., Ni, L., Pan, Y., Chen, Y., Wang, J., Jiang, J. & Shu, C-M. (2022). Safety Criteria for Solid–Liquid Heterogeneous Systems in Semibatch Reactors. ACS Omega 2022 7 (24), 21207-21219

https://doi.org/10.1021/acsomega.2c02139

La tasa de carga del mineral de hierro se ajusta directamente con el instrumento de dosificación de polvo.

Zarl, M. A., Ernst, D., Cejka, J., & Schenk, J. (2022). A New Methodological Approach to the Characterization of Optimal Charging Rates at the Hydrogen Plasma Smelting Reduction Process Part 1: Method. Materials, 15(14), 4767.

https://doi.org/10.3390/ma15144767

Dosificación de mineral de hierro de Carajas.

Ernst, D., Zarl, M. A., Cejka, J., & Schenk, J. (2022). A New Methodological Approach on the Characterization of Optimal Charging Rates at the Hydrogen Plasma Smelting Reduction Process Part 2: Results. Materials, 15(12), 4065.

https://doi.org/10.3390/ma15124065

Montaje experimental de la pirólisis catalítica: Un alimentador programable (LAMBDA DOSER 1L) dispensó gránulos de plástico, normalmente a una velocidad de alimentación de 120 g/h, en el reactor aquartz, que contenía 1 kg de bolas de carburo de silicio de 8 mm. El lecho de bolas se calentó y se mantuvo a 500 °C durante todas las pruebas de este estudio mediante un sistema programable de calentamiento por microondas.

Zhou, N., Dai, L., Lyu, Y., Wang, Y., Li, H., Cobb, K., Chen, P., Lei, H. & Ruan, R. (2022). A structured catalyst of ZSM-5/SiC foam for chemical recycling of waste plastics via catalytic pyrolysis. Chemical Engineering Journal, Volume 440, 2022, 135836, ISSN 1385-8947.

https://doi.org/10.1016/j.cej.2022.135836

2021

Estudio de cristalización de reacción semibatch: El sólido se dosificó mediante un DOSIFICADOR LAMBDA de 0.2 L y se ventiló una corriente lenta de aire a presión a través del dosificador de sólidos. Se utilizaron tres sólidos para la dosificación: CL-20 (150 μm), HMX fino (5 μm) y HMX grueso (300 μm). Mezclando el HMX grueso con el fino en una proporción de 5:1, se consiguió una dosificación reproducible.

Herrmannsdörfer, D., & Klapötke, T. M. (2021). Semibatch reaction crystallization for scaled-up production of high-quality CL-20/HMX cocrystal: efficient because of solid dosing. Crystal growth & design, 21(3), 1708-1717.

https://doi.org/10.1021/acs.cgd.0c01611

Dosificación de sólidos: Se dosificó una mezcla de 90 g de CL-20 (205 mmol), 25 g de HMX grueso (84 mmol) y 5 g de HMX fino (17 mmol) mediante un Dosificador LAMBDA DOSER 0.2L. Se ventiló una corriente lenta de aire a presión a través del dosificador de sólidos para evitar la cementación del sólido debido a los vapores de acetonitrilo.

Herrmannsdörfer, D., & Klapötke, T. M. (2021). Quality Assessment of the CL‐20/HMX Cocrystal Utilising Digital Image Processing. Propellants, Explosives, Pyrotechnics, 46(4), 522-529.

https://doi.org/10.1002/prep.202000341

Diseño experimental para la conversión de NOx, que comprende un reactor de arrastre vertical y sistemas de monitorización de gases: Un dosificador de polvo electrónico calibrado (Lambda Laboratory Instruments) alimenta el plástico reciclado (pulverizado criogénicamente, 150-355 μm) a una tasa de alimentación baja y constante de 7 mg/min, a través de una sonda refrigerada por agua, a un reactor de cuarzo alojado en un horno de tres zonas calentado eléctricamente.

Oluwoye, I., Zeng, Z., Mosallanejad, S., Altarawneh, M., Gore, J., & Dlugogorski, B. Z. (2021). Controlling NOx emission from boilers using waste polyethylene as reburning fuel. Chemical Engineering Journal, 411, 128427.

https://doi.org/10.1016/j.cej.2021.128427

Sistema de alimentación de mineral de hierro y cal: La carga continua se realiza mediante un sistema de alimentación de polvo LAMBDA DOSER 0.2L. El mineral más fino tenía fuertes propiedades adhesivas y provocaba la formación de puentes, lo que se evitó parcialmente precalentándolo en un horno de secado a 120 °C.

Cejka, J. (2021). Parameterevaluierung für den kontinuierlichen Chargiervorgang von Eisenerzen und Zuschlägen im Wasserstoff-Plasma-Schmelzreduktionsprozess. Masterarbeit, Montan Universität Loeben.

https://pureadmin.unileoben.ac.at/ws/files/7814331/AC16360490.pdf (2024 April 02)

Determinación de la solubilidad del ácido itacónico dosificado con un alimentador de sólidos LAMBDA DOSER 0.2L controlado por PLS

Holtz, A., Görtz, J., Kocks, C., Junker, M., & Jupke, A. (2021). Automated measurement of pH-dependent solid-liquid equilibria of itaconic acid and protocatechuic acid. Fluid Phase Equilibria, 532, 112893.

https://doi.org/10.1016/j.fluid.2020.112893

2020

Producción de nanomateriales por plasma: los precursores en polvo se introducen con un alimentador de polvo LAMBDA DOSER que está conectado a la entrada del tubo de trabajo.

Graves, B., Engelke, S., Jo, C., Baldovi, H. G., De la Verpilliere, J., De Volder, M., & Boies, A. (2020). Plasma production of nanomaterials for energy storage: continuous gas-phase synthesis of metal oxide CNT materials via a microwave plasma. Nanoscale, 12(8), 5196-5208.

https://doi.org/10.1039/C9NR08886E

https://www.rsc.org/suppdata/c9/nr/c9nr08886e/c9nr08886e1.pdf (2024 April 02)

Escalado del procedimiento de Dakin-West utilizando ácido glutámico a escala de 100 gramos realizado en una configuración automatizada con un dosificador de sólidos LAMBDA DOSER.

Würdemann, M. A., Niţu, C., De Wildeman, S. M., Bernaerts, K. V., & Orru, R. V. (2020). The Forgotten Pyrazines: Exploring the Dakin–West Reaction. Chemistry–A European Journal, 26(36), 8090-8100.

https://doi.org/10.1002/chem.202000475

Sistema de alimentación de mineral de hierro y cal: El instrumento de dosificación de polvo LAMBDA Hi-DOSER 1L, fabricado por LAMBDA Laboratory Instruments, se utilizó para cargar la mezcla de mineral de hierro y finos aditivos de forma continua en el crisol de acero durante las pruebas.

Naseri Seftejani, M. (2020). Reduction of hematite using hydrogen plasma smelting reduction (Doctoral Thesis, Montanuniversitaet Leoben).

https://pure.unileoben.ac.at/en/publications/reduction-of-hematite-using-hydrogen-plasma-smelting-reduction (26 de febrero de 2024)

Equipo de laboratorio para el proceso de reducción por fundición con plasma de hidrógeno (HPSR): Se utilizó el sistema de dosificación de polvo LAMBDA Hi-DOSER 0.2L para introducir de forma continua ~3 g/min de mineral de hierro hematites de Carajas con el gas (40 % de hidrógeno en argón) a través del electrodo hueco de grafito (HGE, diámetro interior 5 mm).

Zarl, M. A., Farkas, M. A., & Schenk, J. (2020). A study on the stability fields of arc plasma in the HPSR process. Metals, 10(10), 1394.

https://doi.org/10.3390/met10101394

El alimentador (LAMBDA DOSER) se colocó en la parte superior del DTF para alimentar de forma continua y uniforme el carbón pulverizado con un caudal de 0.6 a 0.7 g/min. Se pretende investigar el comportamiento de hidropirólisis del carbón bituminoso pulverizado en un horno de tubo de gota (DTF) con una temperatura de 800-1000 °C.

Gao, R., Dou, B., Chang, Q., Xu, J., Dai, Z., Yu, G., & Wang, F. (2020). Effect of temperature and hydrogen on product distribution and evolution of char structure during pyrolysis of bituminous coal in a drop tube furnace. Shanghai Engineering Research Center of Coal Gasification, East China University of Science and Technology, Shanghai 200237, PR China.

https://doi.org/10.1016/j.fuel.2020.117078

El sistema de alimentación de polvo sólido (LAMBDA Hi-DOSER 1L) se utilizó para alimentar el mineral de hierro premezclado y la cal de forma continua en la zona del arco de plasma durante la operación del arco.

Seftejani, M. N., Schenk, J., Spreitzer, D., & Zarl, M. A. (2020). Slag Formation during Reduction of Iron Oxide Using Hydrogen Plasma Smelting Reduction. Materials 2020, 13, 935;

https://doi.org/10.3390/ma13040935

2019

Preparación y dosificación de la alúmina de alimentación: para eliminar cualquier resto de humedad, la alúmina se mantuvo en un horno a 300 °C durante la noche y después se almacenó en un desecador hasta la prueba de electrólisis. Se utilizó un dosificador LAMBDA DOSER para la alimentación continua de alúmina (velocidades de alimentación: 200 - 400 mg/min).

Medino, C. M. (2019). Improving current efficiency in low-temperature aluminum electrolysis with vertical inert electrodes (Doctoral dissertation).

URI: https://hdl.handle.net/1946/33817 (27 de marzo de 2024)

La hidrólisis enzimática por lotes alimentados se llevó a cabo en un biorreactor: La operación de alimentación de la biomasa pretratada se controló mediante un LAMBDA DOSER programado. (Contenido de humedad del sustrato: 2.38 %).

Tai, C., & Keshwani, D. (2019). System for optimizing fed-batch hydrolysis of biomass. U.S. Patent No. 10,501,766. Washington, DC: U.S. Patent and Trademark Office.

https://patentimages.storage.googleapis.com/a7/d9/fa/6c34de7d414bd1/US10501766.pdf (2024 April 02)

Alimentación de alúmina: Durante la electrólisis, la alúmina (óxido de aluminio) se alimentó continuamente al electrolito con un equipo de dosificación suministrado por LAMBDA Laboratory Instruments. El dosificador LAMBDA DOSER se ajustó para alimentar continuamente alrededor del 70 - 80 % de la alúmina necesaria para realizar la electrólisis al 100% de eficiencia de corriente.

Gunnarsson, G., Óskarsdóttir, G., Frostason, S., & Magnússon, J. H. (2019). Aluminum electrolysis with multiple vertical non-consumable electrodes in a low temperature electrolyte. In Light Metals 2019 (pp. 803-810). Springer International Publishing.

https://doi.org/10.1007/978-3-030-05864-7_98

Configuración experimental: A) sistemas LAMBDA DOSER de alimentación de gas y sólidos; B) zona de reacción y horno eléctrico; C) sistema de detección óptica

Díaz, W., Toro, C., Balladares, E., Parra, V., Coelho, P., Reyes, G., & Parra, R. (2019). Spectral characterization of copper and iron sulfide combustion: A multivariate data analysis approach for mineral identification on the blend. Metals, 9(9), 1017.

https://doi.org/10.3390/met9091017

2018

Gasificador híbrido solar/autotérmico: El tubo de SiC se fabricó con un orificio acodado de 45˚ 16.7 mm de diámetro en la parte posterior para permitir el suministro de materia prima desde un alimentador de partículas por gravedad LAMBDA DOSER a través de un tubo de Al2O3. El alimentador de partículas se purgó con Ar en el recipiente de la materia prima y justo debajo del alimentador a una velocidad constante de 2 LN/min para evitar el reflujo de los gases reactivos. El alimentador se calibró con la purga de Ar a una velocidad de alimentación de ~60 g/h. Las tasas de alimentación con intervalos de confianza del 95% fueron de 57.5 ± 2.7 g/h para el carbón activado y de 62.3 ± 8.81 g/h para el carbón de lignito.

Muroyama, A. P., Guscetti, I., Schieber, G. L., Haussener, S., & Loutzenhiser, P. G. (2018). Design and demonstration of a prototype 1.5 kWth hybrid solar/autothermal steam gasifier. Fuel, 211, 331-340.

https://doi.org/10.1016/j.fuel.2017.09.059

2016

Desarrollo de sistemas de control de lógica difusa para el monitoreo y control de la alimentación en la hidrólisis enzimática de biomasa lignocelulósica (maíz).

Tai, C., Voltan, D. S., Keshwani, D. R., Meyer, G. E., & Kuhar, P. S. (2016). Fuzzy logic feedback control for fed-batch enzymatic hydrolysis of lignocellulosic biomass. Bioprocess and biosystems engineering, 39, 937-944.

https://doi.org/10.1007/s00449-016-1573-1

2015

Para controlar (sobre-secado a 60 %, contenido de humedad de 2.38 %) la operación de suministro de biomasa lignocelulósica para hidrólisis enzimáticas incrementadas.

Tai, C., Keshwani, D. R., Voltan, D. S., Kuhar, P. S., & Engel, A. J. (2015). Optimal control strategy for fed‐batch enzymatic hydrolysis of lignocellulosic biomass based on epidemic modeling. Biotechnology and bioengineering, 112(7), 1376-1382.

https://doi.org/10.1002/bit.25552

Pirólisis y determinación de parámetros cinéticos con el LAMBDA DOSER 1L para alimentación de polvo: El sistema de fluidización alimentó el residuo sólido de hidrólisis ácida (AHR) de miscanthus a un ritmo sustancialmente constante y sin bloqueos. En algunos experimentos, la biomasa cayó repentinamente en el reactor debido a la formación de puentes y a la aglomeración electrostática del material de partida. La aglomeración se destruyó fácilmente dando golpecitos en el recipiente de vidrio. El motor se ajustó a 005 (casi al mínimo) para conseguir caudales inferiores a 1 g/min con un caudal de gas de 8 L/min. Se están estudiando mejoras para conseguir diferentes combinaciones de velocidad de alimentación y caudal de gas con el fin de modificar el tiempo de residencia de los sólidos y la relación de equivalencia para la gasificación.

Cortes Benitez, A. (2015). Thermal processing of miscanthus, sugarcane bagasse, sugarcane trash and their acid hydrolysis residues (Doctoral dissertation, Aston University).

https://publications.aston.ac.uk/id/eprint/25492/3/Thermal_processing_of_miscanthus_sugarcane_bagasse_sugarcane_trash_and_their_acid_hydrolysis_residues.pdf (2024 April 02)

Estudio de aplicabilidad de sales inorgánicas fundidas en el proceso de pirólisis: El dosificador LAMBDA DOSER 0.2L se llenó con el material de alimentación, constituido por materia prima (astillas de madera de haya, lignina Virgen-PET u Organosolv) y una mezcla de sales de carbonato (mezcla de sales de carbonato de Li2CO3 seco (purum)), Na2CO3 (anhidro, flujo libre, Redi-Dri™, reactivo ACS), K2CO3 (anhidro, flujo libre, Redi-Dri™, reactivo ACS) de Sigma-Aldrich Chemie GmbH) y se enjuagó con nitrógeno: Se introdujeron constantemente 5 g de material de alimentación seco durante 20 minutos en el reactor.

Nieberl, M. (2015). Parameterstudie zur thermochemischen Zersetzung organischer Materialien in geschmolzenen Salzen. Bachelor Thesis, Fraunhofer Institut für Chemische Technologie ICT, Pfinztal.

https://doi.org/10.24406/publica-fhg-282280 ,

https://publica-rest.fraunhofer.de/server/api/core/bitstreams/43fc3357-47ba-4bc4-a2d5-b6394d0131c0/content (2024 April 02),

see „Abbildung 3-1 Abbildung der Versuchsanlage“

2014

Partículas transparentes de vidrio y esféricas similares a gotitas de carburantes fueron introducidas a un canal, en cantidades establecidas, utilizando el dosificador de sólidos en polvo LAMBDA DOSER.

Bodoc, V., & Voicu, D. (2014, July). Experimental investigation of the infrared extinction limitations for vapor concentration measurement in a gas/particle flow. In 17th International Symposium on Applications of Laser Techniques to Fluid Mechanics.

HAL Id : hal-01079181 , version 1

https://hal.archives-ouvertes.fr/hal-01079181/document (2024 Feb 22)

Secado y tamizado de partículas de bagazo fueron adicionadas por un alimentador calibrado (LAMBDA DOSER) dentro de la cama de un reactor de tubo para gotas.

Krüsi, M. (2014). Heat transfer enhancement in a solar biomass gasifier. Eidgenössische Technische Hochschule ETH Zürich (Nr. 21821).

https://doi.org/10.3929/ethz-a-010256755

2013

El reactor está equipado con el DOSIFICADOR DE POLVO LAMBDA para suministrar NaBH4 sólido de forma continua

Muir, Sean S. (2013). Sodium borohydride production and utilisation for improved hydrogen storage. PhD Thesis. Australian Institute for Bioengineering and Nanotechnology, The University of Queensland.

https://doi.org/10.14264/uql.2016.540

2012

Alimentación cloruro de cobre en un reactor de cuarzo para producir nanopartículas de carbón recubiertas de cobre por reducción en fase de vapor.

Eiroma, K., Forsman, J., Hult, E.-L., Auvinen, A., Sipiläinen-Malm, T., Alastalo, A., Tapper, U., Leppäniemi, J., Mattila, P., Lyyränen, J., Sarlin, J., Jokiniemi, J., & Mössmer, S. (2012). Water-Based Carbon-Coated Copper Nanoparticle-Fluid Formation of Conductive Layers at Low Temperature by Spin Coating and Inkjet Deposition. Journal of Imaging Science and Technology, 56(4), 40501-1-40501-10 (10).

https://doi.org/10.2352/J.ImagingSci.Technol.2012.56.4.040501

2011

Para utilizarlo como un dispensador para un reactor de tubo para gotas (Drop tube reactor DTR)

Hampp, F., & Janajreh, I. (2011). Development of a drop tube reactor to test and assist a sustainable manufacturing process. In Advances in Sustainable Manufacturing: Proceedings of the 8th Global Conference on Sustainable Manufacturing (pp. 141-148). Springer Berlin Heidelberg.

https://doi.org/10.1007/978-3-642-20183-7_21

Dispensación de cloruro de cobre en una cama de precipitado de aluminio (Al2O3) dentro de un reactor de cristal de cuarzo para nanopartículas con el objetivo de desarrollar una tinta fluida de nanopartículas de carbón recubiertas de cobre.

Eiroma, K., Auvinen, A., Forsman, J., Hult, E. L., Jokiniemi, J., Koskela, P., Sarlin, J., Sipiläinen-Malm, T., & Tapper, U. (2011, January). Development of conductive carbon coated copper nanoparticle inkjet fluid. In NIP & Digital Fabrication Conference (Vol. 2011, No. 2, pp. 458-461). Society for Imaging Science and Technology.

https://citeseerx.ist.psu.edu/doc_view/pid/d22f2a68bdaaa4054fc32e50d30afa87ef2c185c (2024 Feb. 22)

PDF: https://citeseerx.ist.psu.edu/document?repid=rep1&type=pdf&doi=d22f2a68bdaaa4054fc32e50d30afa87ef2c185c (2024 Feb. 22)

2007

Adiciones de partículas programadas en el tiempo para estudiar la evaluación y fabricación de compuestos ferroeléctricos reforzados con matriz metálica.

Poquette, B. D. (2007). Understanding Ferroelastic Domain Reorientation as a Damping Mechanism in Ferroelectric Reinforced Metal Matrix Composites (Doctoral dissertation, Virginia Tech).

https://hdl.handle.net/10919/29169 (2024 Feb. 22)

What is the lead time of Powder Doser?

We have DOSERs in stock and it can be delivered to you within a few days from order. Practically, it is only the time taken for shipping

Do you accept Credit Card payments?

You can pay using your credit card via PayPal. Most importantly, it is not necessary to have a PayPal account to make the payment via credit card.

Could you please confirm the particle size that can be fed by the dosing system?

The biggest particle size for powders that could be dosed with our DOSER is about 4 mm. A good dosing of powders depends essentially on the flowing properties of the respective powders to be dosed. In general, homogeneous and free-flowing powders can be dosed best.

How does the LAMBDA DOSER work with the substances which are prone to agglomeration?

The powder / granules / solid must be properly treated for good flowing properties It is also possible to allow a gas flow to pass through the Lambda dosing vessel in order to create a controlled atmosphere.

It is often possible to substantially improve the flowing properties of the respective powder / granules / solid by adding Aerosil (fumed silica – pure SiO2) to your powder (~0.1 - 2% by weight).

How the LAMBDA DOSER reacts to abrasive powders?

In the case of abrasive materials being used with the LAMBDA Powder DOSER, you will have an opportunity to replace the glass vessel and / or the distributors as needed.

What is the accuracy of the each dispensing?

The motor of the driving unit is controlled with quartz-driven electronics, similarly as it is done in electronic watches.Therefore, the accuracy depends mainly on the powder. For best accuracy and precise doses, the powder needs to be free-flowing and homogeneous.

Can the DOSER control the mass flow rate (g/min) of the powder being dispensed?

It is always possible to control the mass flow rate of the powder using the LAMBDA Doser. You could program the DOSER up to 27 pairs of speed and time settings to control your desired mass flow rate (g/min).

Is it possible to control the DOSER via Mettler Toledo titroprocessor to dispense NaF to the titration process when required?

Yes, the powder DOSER can be controlled by Mettler Titration Excellence T50/T70/T90 via RS-232 communication (most common type of connection with Mettler accessories), to dispense the desired amount of powder to the titration process.

The powder DOSER has to be included as RS-232 control in the titroprocessor unit and the desired activity can be selected (e.g.: the signal would switch off the DOSER or switch it on, etc.)

For integration of DOSER with your Mettler titroprocessor, you would need the RS-232 interface activated in the powder dosing unit and RS-232 connection cable.