Optimized Feeding of Zeolite SiOLITE® with the LAMBDA Powder DOSER for Fluidized Bed Methanol Production

Research conducted by the Catalysis and Reactor Engineering Group (CREG), Aragon Institute of Engineering Research (I3A), University of Zaragoza, has demonstrated that methanol synthesis from CO₂ can be significantly enhanced through the use of a sorbent. Fresh sorbent was continuously introduced into a fluidized bed reactor and separated from the catalyst bed by segregation, enabling stable steady-state operation. A conventional CuO/ZnO/Al₂O₃ catalyst was combined with SiOLITE® zeolite (crystalline aluminosilicate minerals) as the sorbent, with different particle sizes and proportions tested to study fluid dynamics and segregation in catalyst–sorbent mixtures.

Reference: Menéndez, M., Ciércoles, R., Lasobras, J., Soler, J., & Herguido, J. A. (2024). Preliminary assessment of sorption-enhanced methanol synthesis in a fluidized bed reactor with selective addition/removal of the sorbent. Catalysts, 14(409). doi.org/10.3390/catal14070409

The team achieved a mixing index of 0.31, confirming effective segregation and reliable operation with minimal catalyst loss—only 0.005 g/min under optimal conditions. Continuous sorbent feeding and removal were demonstrated with very low catalyst carryover. MATLAB reactor simulations further confirmed that sorbent addition considerably improves methanol yield, either by enabling lower-pressure operation or achieving higher per-pass conversions. This proof of concept highlights the potential of sorption-enhanced methanol synthesis in fluidized bed reactors as a more efficient and scalable alternative to conventional processes.

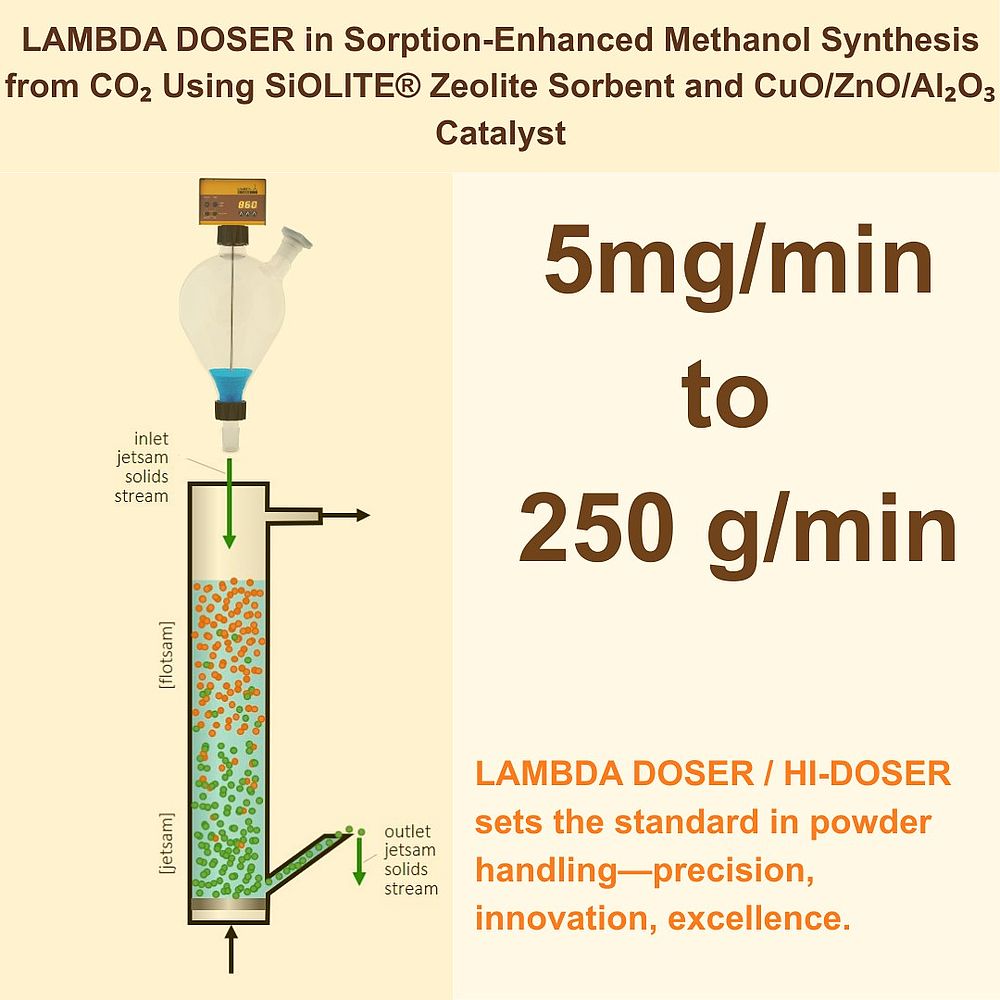

Application of the LAMBDA DOSER in Continuous Sorbent Addition

An important part of this research was the ability to continuously add sorbent to the reactor in a controlled and reproducible manner. For this purpose, the LAMBDA DOSER solid dispenser was used to introduce the sorbent at the top of the bed, forming the inlet jetsam solids stream.

The reactor was loaded with a binary mixture of catalyst and sorbent (30 vol% CuO/ZnO/Al₂O₃ – 70 vol% Zeolite-SiOLITE®) and operated under carefully adjusted conditions. Initial experiments showed higher catalyst loss due to gas leakage through a side outlet, which reduced the effective gas flow needed for proper fluidization. After correcting the nitrogen flow to 1429 mL/min, the system operated under optimal conditions, ensuring efficient segregation of catalyst and sorbent.

During one-hour experiments, solids exiting the system were sampled every ten minutes to evaluate catalyst losses. In total, 12.3 g of catalyst and 38.4 g of sorbent were used. The tests confirmed that most of the sorbent was removed from the jetsam zone while new sorbent was continuously introduced, maintaining segregation throughout operation. Catalyst losses were extremely low—always under 0.6%, and less than 0.1% under the best condition.

Conclusion

The LAMBDA DOSER was instrumental in enabling continuous, precise sorbent addition to the fluidized bed reactor, ensuring effective segregation from the catalyst and minimizing catalyst loss. Its controlled dosing allowed reproducible operation, facilitating stable steady-state conditions and validating the concept of sorption-enhanced methanol synthesis.

By enabling continuous sorbent addition and removal with minimal disruption, the LAMBDA DOSER contributed to higher methanol yields and demonstrated the feasibility of scaling this approach for industrial applications. This work highlights a reliable, efficient, and controllable strategy for CO₂-to-methanol conversion using fluidized bed reactors.

What Makes LAMBDA DOSER and HI-DOSER Powder Dispenser Unique?

The LAMBDA DOSER features quartz-driven electronics that precisely control the motor of the driving unit, similar to the mechanisms used in high-precision electronic watches. Its open-spiral powder distributor design prevents compaction and blockages, ensuring smooth and consistent dosing by efficiently channeling powder toward the center for dispensing.

Both the LAMBDA DOSER and HI-DOSER are ideal for laminar hoods, automating the precise dispensing of powders and replacing slow manual processes. Integration with a weighing balance allows the accurate dispensing of specific weight portions.

These feeders offer highly adjustable dosing rates over three orders of magnitude. For example, the DOSER can deliver NaCl at rates ranging from 50 mg/min to 50 g/min. The HI-DOSER operates in slow mode (60 mg/min to 60 g/min) and fast mode (250 mg/min to 250 g/min) under standard laboratory conditions, and specialized configurations can achieve rates as low as 10 mg/min.

Vessels for the DOSER and HI-DOSER are available in 0.2 L, 1 L, 3 L, and 6 L sizes, with optional protective coatings for enhanced safety during handling and operation.

For more information on the LAMBDA DOSER and HI-DOSER, visit www.lambda-instruments.com/powder-doser. For inquiries or quotations, contact us at sales@lambda-instruments.com.