From Earth to Orbit: How LAMBDA Peristaltic Pump Powers NASA’s Next-Generation Life Support Systems

For decades, LAMBDA peristaltic pumps have earned a reputation for precision and reliability in laboratories worldwide. Now, our technology has reached a new frontier, playing a key role in two landmark NASA projects developing advanced life support systems for future deep-space missions.

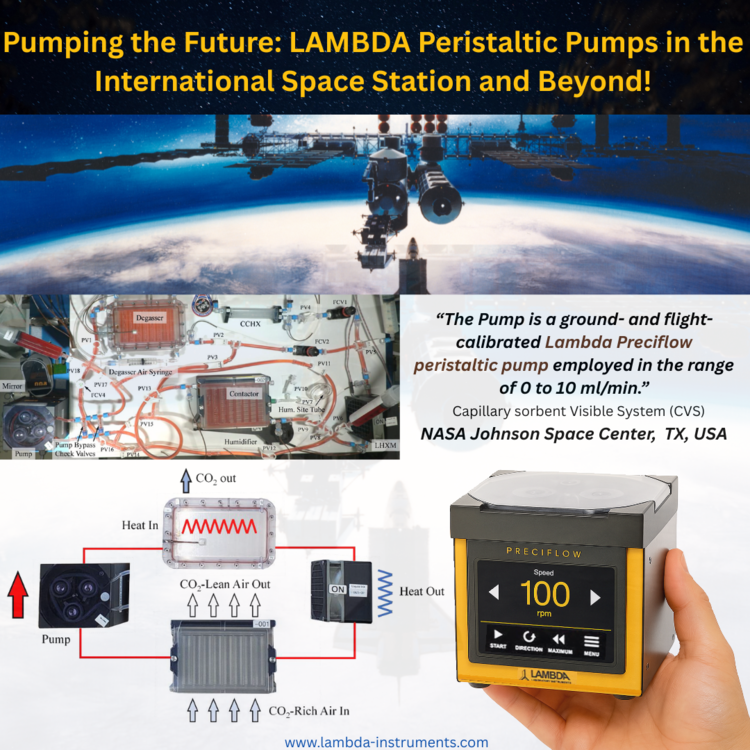

The Capisorb Visible System (CVS) was a NASA experiment designed to test a new method for removing carbon dioxide from the air aboard the International Space Station (ISS). The system's innovative design used a passive, open-channel fluidic device that includes the LAMBDA peristaltic pump to manage the flow of liquid sorbent.

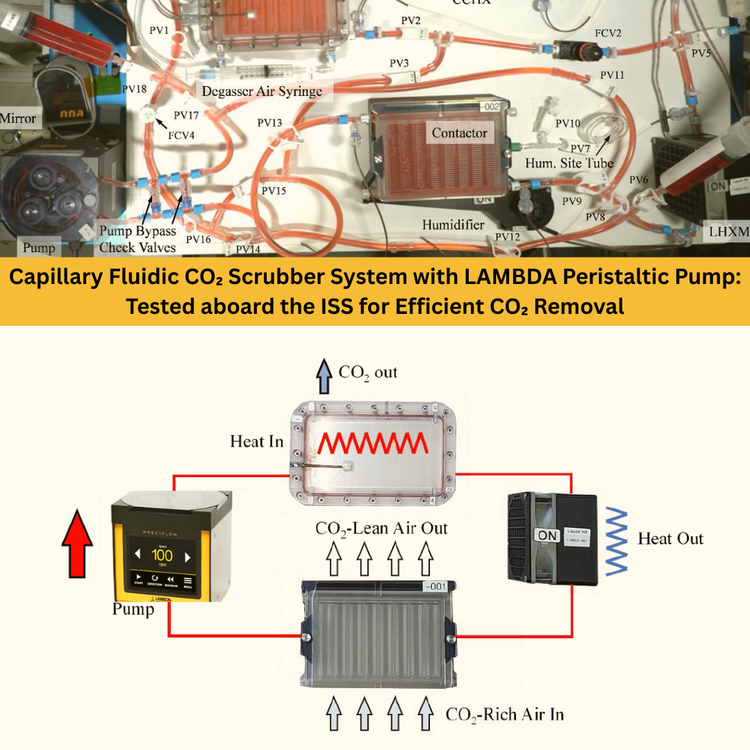

In the CVS, the LAMBDA peristaltic pump was responsible for moving the liquid sorbent between the Contactor, where the CO2 was absorbed, and the Degasser, where it was removed, enabling a continuous, closed-loop process. The ability of the pump to operate with high reliability and precision in microgravity was essential for the successful flight demonstration on the ISS, proving the viability of this advanced air revitalization technology for future space missions.

Ground-Based Development

The test highlights the ground-based development of the Capisorb Visible System—a full-scale prototype using an amine sorbent. The LAMBDA PRECIFLOW pump circulates the fluid between absorber and desorber, maintaining the steady flow rates required. These tests validated the pump’s ability to meet the strict tolerances of a system destined for space.

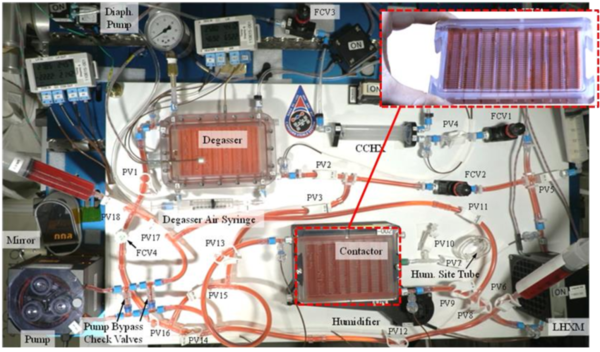

Fig 1: The Capisorb Visible System (CVS) experiment assembly

Reference: Torres, L. J., Weislogel, M. M., Chen, Y., Krishcko, O., Jenson, R. M., Belancik, G. A., Alcid, M., Levri, J. A., Hand, L. A., Cortez, A., Heavner, S., & Graf, J. C. (2024, July 21). A capillary fluidic CO₂ scrubber for spacecraft: The liquid amine carbon dioxide removal assembly (NASA Technical Publication). Texas Tech University Institutional Repository. ttu-ir.tdl.org/items/accab4f0-46c7-4204-8248-d4bcec1bd362

In-Orbit Testing on the International Space Station

The Capillary Sorbent Visible System (CVS) experiment conducted aboard the International Space Station. Launched on the SpaceX CRS-27 mission, the experiment used a non-toxic liquid to demonstrate capillary-based CO₂ removal in microgravity. Once again, the LAMBDA PRECIFLOW pump circulated the liquid from the contactor (absorber) to the degasser (desorber), proving its performance in zero-gravity conditions.

Fig 2: Capillary Fluidic CO₂ Scrubber System with LAMBDA Peristaltic Pump: Tested aboard the ISS for Efficient CO₂ Removal

Reference: Weislogel, M. M., Torres, L. J., Krishcko, O., Jenson, R. M., Levri, J., Belancik, G., Jan, D., Heavner, S., Hand, L. A., & Graf, J. C. (2024, July 21–25). Capillary fluidic CO₂ scrubbing aboard spacecraft: The CVS demonstration on ISS: Part I Overview. 53rd International Conference on Environmental Systems (ICES-2024-113). Texas Tech University Institutional Repository. ttu-ir.tdl.org/items/c02fcb1b-c4aa-462f-ba33-540e8c2a60c1

The LAMBDA Peristaltic Pump Advantage: Engineered for Excellence

- Long-Term Reliability: Large-diameter bearings reduce mechanical stress, extending tubing life and ensuring consistent flow rates.

- Precision and Control: Microprocessor-controlled motors provide precise fluid dosing, digital speed control, and programmable flow profiles.

- Safety in Any Environment: Pumps operate without increasing pressure, even if the fluid line becomes blocked, perfect for microgravity conditions.

- Cost-Effective and Simple: Unique pump head design allows low-cost tubing, reducing expenses and simplifying maintenance.

Versatile Applications of LAMBDA Peristaltic Pumps

Chromatographic Techniques

- Compact and stackable, ideal for chromatography—used standalone or with OMNICOLL fraction collector and autosampler.

- Applications: Liquid chromatography, sample collection, fractionation, gradient elution, column saturation, PC-controlled gradient pump via PNet software.

Fermentation & Cell Culture

- Designed for long-term sterile processes, supporting continuous bioprocessing with sterilizable tubing.

- Applications: Feed/harvest, pH & antifoam control, timed sampling, nutrient dosing, media dispensing, growth tracking.

Chemical & Biochemical Reactions

- Applications: Titration, pH-stat control, controlled reagent addition, reaction rate visualization, enzyme activity measurement.

Single-Use Systems & Pharmaceutical Research

- Applications: Sterile filtration, cell suspension handling, drug trials, process validation.

Ready to elevate your research? Explore the LAMBDA Peristaltic pumps today and discover how they can transform your work with precise liquid transfer. Contact us at sales@lambda-instruments.com for more information. More info at www.lambda-instruments.com.