Lab scale Bioreactor for Cultured Meat Production and Research

Cultured meat is produced by growing animal cells in a controlled bioreactor environment. This technology is becoming increasingly important as a sustainable alternative to conventional meat production, helping reduce environmental impact, antibiotic use, and dependence on livestock farming. Developing cultured meat requires reliable bioreactor systems capable of maintaining precise and stable cultivation conditions to support cell growth and differentiation.

A lab-scale bioreactor is essential for cultured meat research, process development, and optimization. It allows researchers to accurately control critical parameters such as oxygen supply, nutrient distribution, temperature, and mixing conditions. Proper control of these factors is necessary to ensure high cell viability, reproducible results, and efficient cultured meat production.

Challenges with Conventional Bioreactors for Cultured Meat

Several types of bioreactors for cell culture and cultured meat research are currently used. However, conventional systems often present limitations, particularly when working with sensitive mammalian cells and stem cells.

Stirred Tank Bioreactors

Stirred tank bioreactors are widely used due to their scalability and process control. However, the rotating impellers generate high shear stress, which can damage delicate cultured meat cells and reduce viability. Foam formation and vortex effects can negatively influence culture stability. In addition, when microcarriers are used, cell harvesting may become difficult.

Airlift Bioreactors

Airlift bioreactors use gas flow to mix the culture medium, reducing mechanical stress. However, mixing efficiency decreases at higher cell densities, leading to uneven oxygen and nutrient distribution. Maintaining consistent conditions during scale-up can also be challenging.

Rocking Motion Bioreactors

Rocking motion bioreactors provide gentle mixing but have limitations in scalability and efficiency. Mixing and oxygen transfer decrease at larger volumes, and disposable bags increase operating costs.

LAMBDA MINIFOR – Advanced Bioreactor for Cultured Meat Research

The LAMBDA MINIFOR lab-scale bioreactor is specifically designed to meet the requirements of cultured meat production and advanced cell culture applications. It provides precise environmental control and an innovative gentle mixing system that protects sensitive cells while ensuring efficient oxygen transfer and nutrient distribution.

Gentle Mixing Technology for Sensitive Cell Cultures

Unlike conventional systems that use rotating impellers, the LAMBDA MINIFOR bioreactor uses a non-rotational up-and-down agitation system with biomimicking fish-tail agitation discs made of soft, flexible silicone.

This advanced mixing technology provides:

Very low shear stress, protecting sensitive cells

Gentle mixing ideal for mammalian and stem cells

Improved cell viability and growth performance

Uniform oxygen and nutrient distribution

Reduced foam formation and stable culture conditions

The flexible silicone agitation discs gently move the culture medium without damaging cells, making the system an ideal bioreactor for cultured meat production.

Stable Culture Conditions and Reliable Process Control

The LAMBDA MINIFOR bioreactor provides precise control of temperature, aeration, and mixing, ensuring stable and reproducible cultivation conditions. The integrated infrared heating system delivers uniform temperature control, protecting sensitive cells and supporting optimal growth.

The shaft-free agitation system reduces contamination risk, improves sterility, and minimizes maintenance requirements.

Reduce Media Costs with Flexible Working Volume from 35 mL to 6 L

The LAMBDA MINIFOR lab-scale bioreactor offers a wide working volume range from 35 mL to 6 liters, making it highly suitable for cultured meat research and process optimization. Researchers can perform experiments at small working volumes, significantly reducing the use of expensive culture media and growth factors.

This flexibility provides major advantages:

Lower media and reagent costs during early-stage optimization

Efficient process development using small working volumes

Easy scale-up within the same bioreactor system

Consistent performance from research to process development

Cost-effective solution for cultured meat and cell culture applications

Suitable Bioreactor for Cultured Meat and Multiple Cell Types

Cultured meat production often involves not only animal cell culture, but also microorganisms such as yeast, microalgae, and bacteria, which are used to produce growth factors, nutrients, and supporting components. Therefore, selecting a bioreactor suitable for multiple cell types is essential.

The LAMBDA MINIFOR bioreactor is suitable for: Cultured meat cell cultivation, Mammalian cell culture, Stem cell research, Yeast cultivation, Microalgae cultivation, Bacterial fermentation etc.

Cell types used in cultured meat include:

- Muscle Satellite Cells (Myoblasts)

- Mesenchymal Stem Cells (MSCs)

- Fibro-Adipogenic Progenitor Cells (FAPs)

- Adipocytes (Fat Cells)

- Pluripotent Stem Cells (PSCs) including Induced Pluripotent Stem Cells (iPSCs) and Embryonic Stem Cells (ESCs)

This makes the MINIFOR a versatile lab-scale bioreactor suitable for cultured meat research, biotechnology, and alternative protein development.

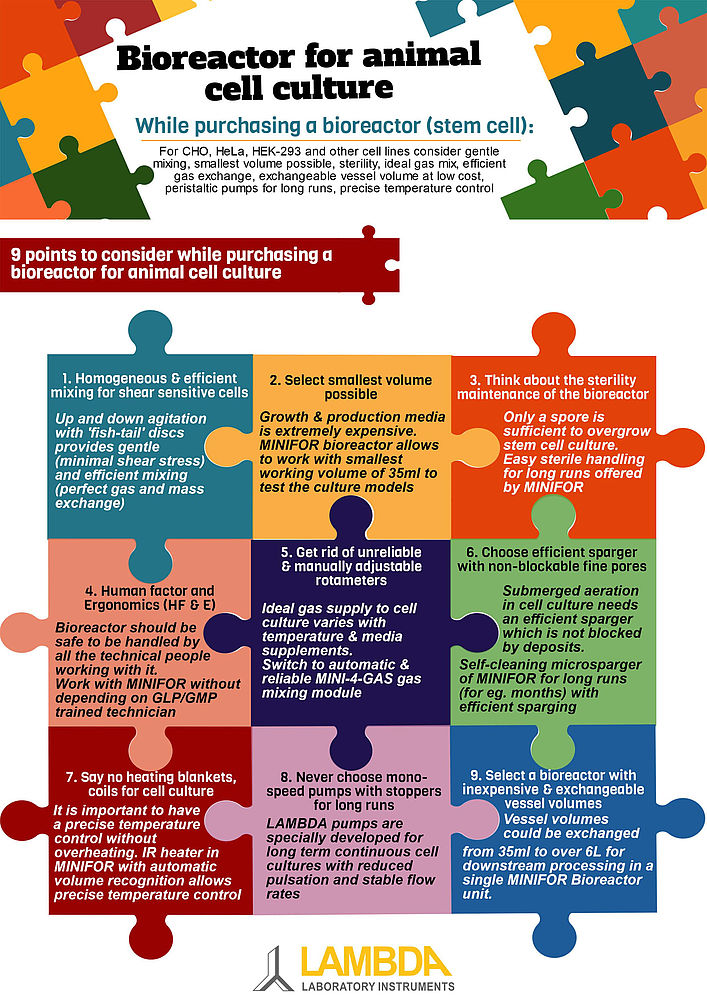

Figure: Practical Considerations for Choosing a Bioreactor for Stem Cell Cultivation and Cultured Meat Research

Ideal Lab-Scale Bioreactor for Cultured Meat Development

The LAMBDA MINIFOR bioreactor provides an advanced and reliable solution for cultured meat production and cell culture research. Its gentle biomimetic mixing technology, precise process control, flexible working volume, and multi-application capability make it an ideal choice for laboratories, research institutions, and biotechnology companies.

This bioreactor for cultured meat ensures high cell viability, stable cultivation conditions, and efficient process optimization, supporting the development of the next generation of cultured meat technologies.