FNet - Fermentor Control Software

FNet - Fermentor Control Software

FNet is a software for monitoring fermentation and cell culture processes with the LAMBDA MINIFOR laboratory fermenter. The software runs under Windows NT, 2000, XP, Vista, 7, 8 and 10:

FNet - Fermentor Control Software - Description of fermentation software

Apart from the direct parameter control on the display, a process control system (PCS) for fully automatic control of the reaction and data storage is available.

Our experience shows that there is a big advantage to follow any culture and measure all the available parameters continuously. Cultures are very complex and a record of the parameters can show the reaction kinetics and for example, comparison of different experiments.

Work done with the MINIFOR fermentor-bioreactor is much more important and the results are much more valuable than the investment into a control system. Minifor can be used without an additional software, because all electronic control systems included in Minifor. And it is possible to upgrade the fermentation software at a later stage.

FNet is the PC remote control software to monitor and control the fermentation and cell culture processes of the LAMBDA MINIFOR Fermentor and Bioreactor system along with the peristaltic pumps and integrators.

The instruments are connected to the computer through a RS-232 or RS-485 interface.

The software recognizes the connected fermenters and bioreactors at the start-up.

Ready to use software

- Easy to install

- The software recognizes the connected fermenters at start-up. Up to 6 fermenters, 12 pump-flow integrators and 6 peristaltic pumps can be connected to one PC.

- No need of programming knowledge

- All cables are easy to connect and have standard connectors

- No special add-in or license to buy for the connection of new fermentors

Display and graphs

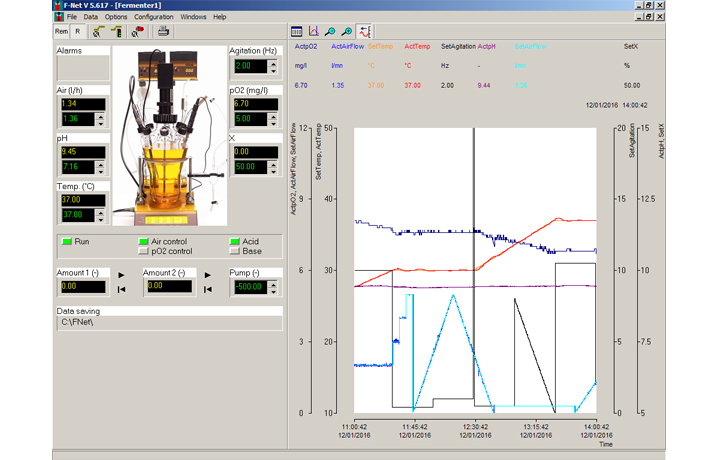

All the information (actual values, set points, graphs, alarms) of the fermenter is presented in the main window:

- Actual values like temperature, pH, pO2, air flow rate, amount of base and acid, and an additional parameter X which could be for example the culture weight for continuous processes, optical density or an online biomass concentration measurement.

- Set point values like temperature, pH, pO2, air flow rate, agitation, another parameter X and one feed with a peristaltic pump

- Scalable graphs: The user can choose the fermenter parameters it wants to display as a function of time

- Ruler to read values on the graphs

Data archive

The process data (temperature, pH,...) are stored in a text file. This file can be exported to most programs on the market for statistical treatment or reporting. More fermentation batches can then be compared for process optimization.

Fermentation process plot - Information provided by LAMBDA pumps together with the INTEGRATOR

We offer SIAM industrial fermentation software for highly sophisticated control options, for example: redox potential measurement (ORP), MINI-4-GAS automatic gas mix, turbidostat, pCO2, etc.