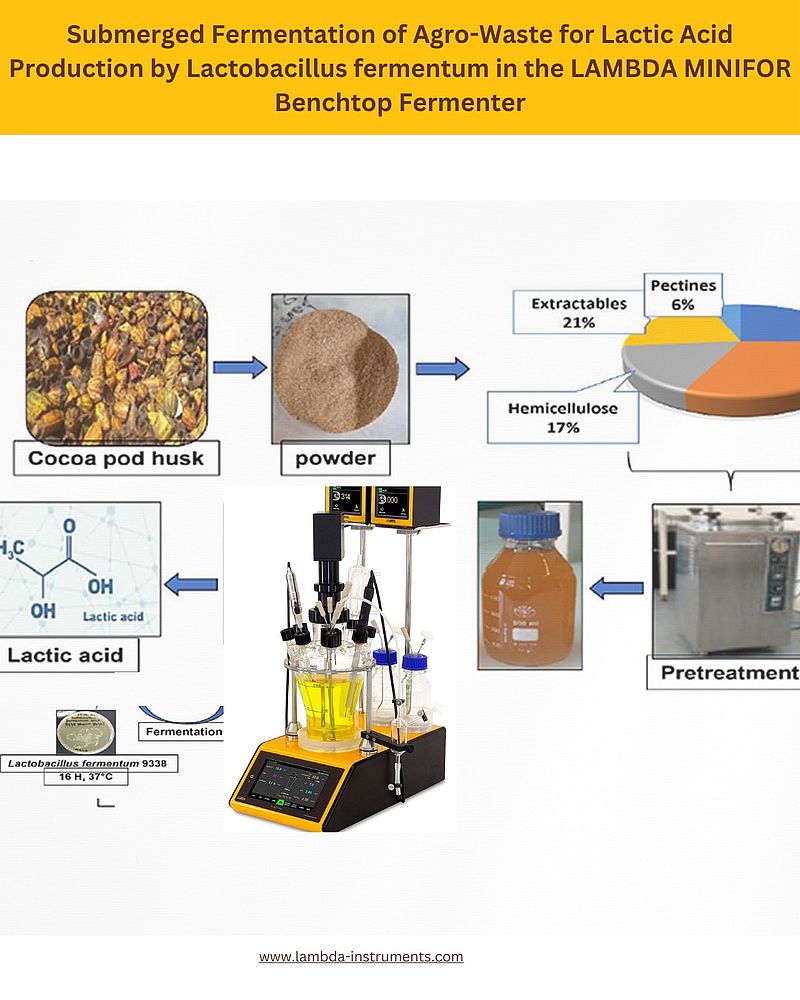

Submerged Fermentation Using the LAMBDA Minifor Benchtop Fermenter for the production of Lactic Acid

In recent years, there's been growing interest in using agricultural waste as a raw material for producing valuable biochemicals. Among these, lactic acid stands out—not just for its wide range of applications in food, cosmetics, and biodegradable plastics—but also for how efficiently it can be produced through microbial fermentation.

A team from Côte d’Ivoire, Niger, Canada, and China, working with detoxified cocoa pod husk hydrolysate, demonstrates the valorize cocoa pods husks into lactic acid. The team used the LAMBDA Minifor benchtop fermenter in the research setting to produce lactic acid from cocoa pod husks (CPH), an underutilized byproduct of the chocolate industry. The process relied on Lactobacillus fermentum ATCC 9338 and submerged fermentation techniques under precisely controlled conditions.

Reference and credit: Ouattara, L. Y., Konan, A. T. S., Mahamane Nassirou, A. K., Ali, S., Mabia, A. G., Kouassi, E. K. A., Soro, D., Yao, K. B., Drogui, A. P., & Tyagi, D. R. (2025). Use of Cocoa Pods Husks (Theobroma cacao L.) as a Potential Substrate for the Production of Lactic Acid by Submerged Fermentation Using Lactobacillus fermentum ATCC 9338. Waste and Biomass Valorization. doi.org/10.1007/s12649-025-03010-y

Lactic Acid Production from Cocoa Pod Husks

In a research setup using Lactobacillus fermentum ATCC 9338, the LAMBDA Minifor was used to ferment a hydrolysate derived from cocoa pod husks—a sugar-rich, pretreated lignocellulosic feedstock. With no additional nutrients added—thanks to the nutritional richness of the cocoa pod husk hydrolysate, the LAMBDA Minifor Fermenter maintained stable conditions over 72 hours:

- Temperature: Maintained at 37°C

- pH: Maintained between 5.5–6.0. Automatically regulated using the LAMBDA Peristaltic pumps

- Agitation: 240 rpm (4 Hz)

- Aeration: Limited to create microaerophilic conditions suited to the bacterial strain

During fermentation, Lactobacillus fermentum ATCC 9338 exhibited strong performance and tolerance to inhibitory compounds. This setup resulted in:

- 26.6 g/L of lactic acid, with a productivity of 1.25 g/(L·h)

- Efficient consumption of glucose and xylose

- Minimal by-product formation (only 3.1 g/L of acetic acid)

- Significant reduction of fermentation inhibitors (e.g., furfural by 74.99%), indicating the strain’s capacity for bio-detoxification during fermentation

The integrated conversion of cocoa pod husks into lactic acid offers a promising pathway for improving circularity within the cocoa industry. By transforming a common agricultural byproduct into a valuable biochemical, this approach aligns with sustainable bioprocessing goals. A key step in this process involves delignification using potassium hydroxide (KOH), which, after removing extractable compounds, significantly enhances lignin breakdown and boosts the availability of fermentable reducing sugars—critical for efficient microbial fermentation.

During fermentation, the LAMBDA MINIFOR played a central role by maintaining tight control of pH, temperature, and agitation. Its unique up-down agitation system ensured gentle yet effective mixing, while automated control systems enabled uninterrupted operation over 72 hours. These capabilities allowed to efficiently metabolize 45.55 g/L of glucose and 12.21 g/L of xylose, yielding 26.61 ± 0.61 g/L of lactic acid and 3.12 ± 0.02 g/L of acetic acid. Furthermore, the strain showed notable tolerance to inhibitors, achieving a 74.99% reduction in furfural.

Benchtop Fermenter-Bioreactor for the Bioprocess Challenges

The LAMBDA Minifor Fermenter is a full-featured laboratory bioreactor with capabilities typically found only in large, expensive systems. Designed for ease of use without compromising on control, the LAMBDA Minifor Fermenter offers:

- Integrated innovative temperature control with fast response and uniform heat distribution

- Precise pH regulation using the LAMBDA peristaltic pumps - Automatic pH regulation

- Up-down biomimetic agitation system that ensures excellent mixing without cell damage

- Modular setup for aerobic or anaerobic conditions, suitable for a wide range of microorganisms

- Digital control interface with data logging and remote monitoring options

In lactic acid fermentation, especially from lignocellulosic sources like cocoa pod husks, controlling pH, temperature, and oxygen exposure is essential. The Minifor fermenter makes it easy to maintain those parameters with precision over multi-day fermentation runs.

What Sets the LAMBDA Minifor Fermenter Apart?

Unlike traditional stirred-tank fermenters, the Minifor fermenter was developed with real laboratory workflows in mind. It combines engineering precision with user accessibility:

- Compact footprint (Just like an A4 sheet): Fits easily into small lab spaces

- No complex setup (Elimination of heavy head plates, baffles etc): Ready to use with minimal practical experience.

- Expandable: Can be configured with sensors, gas mixers, or additional vessels from 35ml to 6l working volume

- Economical: Offers high-end features without the high-end price tag

Researchers working with sensitive cultures, variable substrates, or complex processes appreciate how reliably the LAMBDA Minifor fermenter maintains setpoints—even during long fermentations. For instance, a biotechnology research team using the LAMBDA Minifor feremnter for probiotic fermentation reported consistent pH and temperature control across multiple batches, significantly reducing variability and saving time on recalibrations. during long fermentations.

Ideal for Researchers, Educators, and Startups

Whether you're optimizing a microbial strain, screening feedstocks, or developing waste valorization pathways, the LAMBDA Minifor fermenter provides the tools needed for meaningful, reproducible results. It’s used not only in academic and industrial R&D but also in teaching labs where students need hands-on experience with real-world bioprocess equipment.

The LAMBDA Minifor fermenter isn’t just another lab fermenter—it’s a versatile, reliable, and intelligent platform built for real fermentation challenges. Its performance in submerged fermentation—such as lactic acid production from agro-waste—is a testament to its design and engineering.

Conclusion

If your work involves microbial fermentation, media optimization, or the valorization of renewable substrates, the LAMBDA Minifor ferementer gives you the control and insight needed to advance with confidence.

Interested in integrating the Minifor fermenter into your bioprocess workflow?

Contact us for technical details, configuration options, or to arrange a Teams/Zoom meetings. Email us: sales@lambda-instruments.com