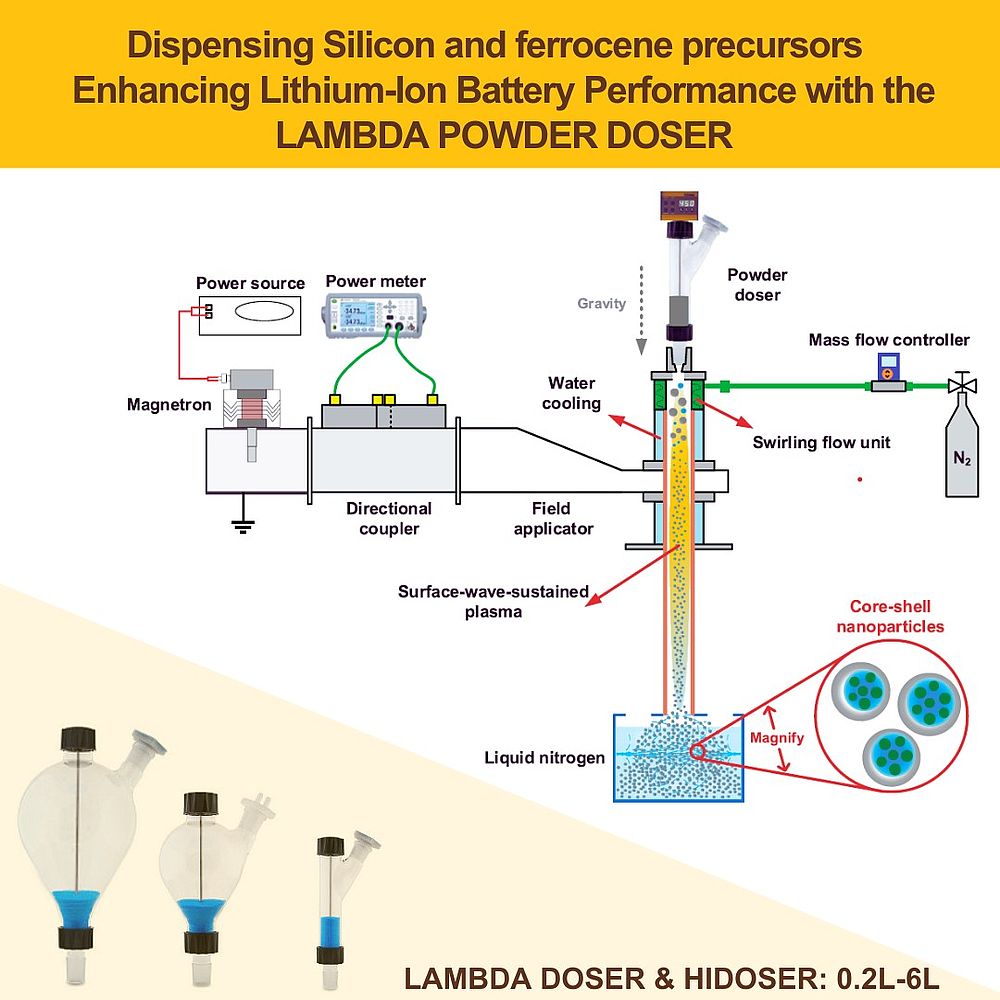

LAMBDA POWDER DOSER is used in the synthesis of the silicon-based core-shell nanoparticles with the SWS plasma

LAMBDA POWDER DOSER for Dispensing Lithium-Ion Battery Precursor - Silicon and Ferrocene Mixture in the Lithium Battery improvisation study.

Lithium-ion batteries (LIBs) are highly regarded in various applications, including portable electronics, electric vehicles, and aerospace, thanks to their superior energy density and higher voltages. Commercial LIBs typically use graphite for the anodes due to its longevity, availability, and cost-effectiveness. However, graphite's specific capacity is becoming insufficient for high-energy demands. Silicon, with its tenfold higher theoretical capacity is a promising alternative. Yet, it faces capacity issues due to significant volume changes during lithium insertion/extraction.

To address this, Chinese researchers developed a method to embed silicon nanoparticles within conductive layers like graphene. They accomplished this through an ultra-fast, one-step, and scalable process for synthesizing graphene@Fe–Si nanoparticles using atmospheric pressure surface-wave-sustained plasma.

Fig 1: The 0.2L LAMDBA DOSER fixed to the SWS plasma generator for the synthesis of the silicon-based core-shell nanoparticles.

Precise control of the precursor material is vital to ensure the even coating of graphene onto the surface of Fe–Si composite nanoparticles using SWS plasma. To achieve this, the research team employed the LAMBDA POWDER DOSER, allowing them to uniformly feed precursor powder into the plasma reaction zone in a well-regulated environment. They used a combination of ferrocene and silicon powder as precursor materials, introducing them at a consistent flow rate of 1 g/min.

Reference: Jie, Z., Zhang, Z., Bai, X., Ma, W., Zhao, X., Chen, Q., & Zhang, G. (2023). Surface-wave-sustained plasma synthesis of graphene@Fe–Si nanoparticles for lithium-ion battery anodes. In Applied Physics Letters (Vol. 123, Issue 11). AIP Publishing. https://doi.org/10.1063/5.0159269

Conclusion:

They conducted verification of the synthesized nanoparticles, which encompassed graphene cladding and silicon nanoparticles encapsulated in iron, through a range of analytical techniques. These techniques included energy-dispersive x-ray spectroscopy mapping, line scanning in transmission electron microscopy mode, and high-resolution transmission electron microscopy. Additionally, they utilized Raman spectroscopy to confirm the identity of the cladding as graphene. This study introduces a viable strategy for industrial-scale production of anode materials, aiming to enhance the performance of lithium-ion batteries (LIBs).

How LAMBDA DOSER and HI-DOSER is unique from other dispensers:

The LAMBDA feeder offers a unique advantage with its quartz-driven electronics controlling the motor of the driving unit, akin to those found in electronic watches. Unlike other systems, the open spiral design of the powder distributor prevents compaction and blockages, ensuring smooth dosing. This spiral efficiently channels the powder to the center for dispensing.

The LAMBDA DOSER/HI-DOSER finds application in laminar hoods for the precise dispensing of various powders, replacing time-consuming manual processes with swift automation. Integration with a weighing balance facilitates the dispensing of specific weight portions.

With the powder DOSER and HI-DOSER, dosing rates can be adjusted extensively, spanning a range of 3 decades. For example, the DOSER allows a dosing range of NaCl from 50 mg/min to 50 g/min, while the HI-DOSER operates in slow mode (60 mg/min to 60 g/min) and fast mode (250 mg/min to 250 g/min) under standard laboratory conditions. For specialized applications, the feeder can be configured to dispense rates as low as 10mg/min.

The DOSER and HI-DOSER models can be supplied with vessels of 0.2 L, 1 L, 3 L, or 6 L, optionally coated with a protective film for added safety during handling and operation.

For further details on the LAMBDA powder feeder DOSER and HI-DOSER, visit www.lambda-instruments.com/powder-doser/. For inquiries or quotations regarding the DOSER/HI-DOSER powder feeder, please reach out to us at sales@lambda-instruments.com