Use of the LAMBDA DOSER as an Alumina Feeder in Inert-Electrode Aluminum Electrolysis

In laboratory-scale aluminum electrolysis, accurate and reliable alumina feeding is essential for stable cell operation and meaningful process evaluation. In the study “Characterization of Off-Gases from an Inert Electrode Aluminum Electrolysis Cell”, the LAMBDA POWDER DOSER was used to feed smelter-grade alumina during electrolysis experiments conducted as part of the EU-funded REVEAL project.

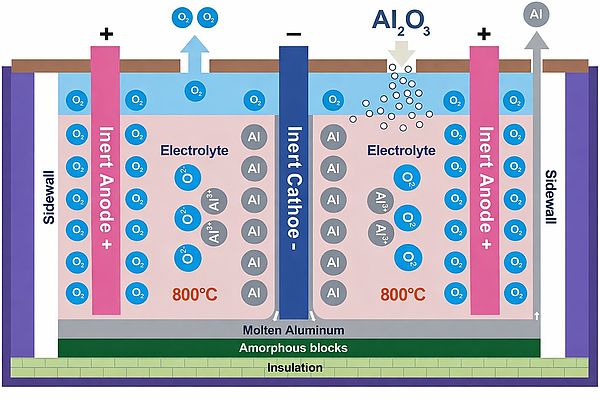

The experiments were carried out in a inert-electrode electrolysis cell operating at approximately 800 °C. Unlike conventional Hall–Héroult cells, the inert-electrode configuration eliminates carbon anodes and produces oxygen as the main reaction gas. Under these conditions, controlled alumina addition becomes particularly important to avoid voltage instability and to maintain electrolyte composition.

Fig 1: Overview of the Electrode Configuration in the Aluminum Electrolysis cell (Reference: Senanu, S., Gunnarsson, G., Gunnarsson, D. et al. Characterization of Off-Gases from an Inert Electrode Aluminum Electrolysis Cell. J. Sustain. Metall. (2025). doi.org/10.1007/s40831-025-01348-0

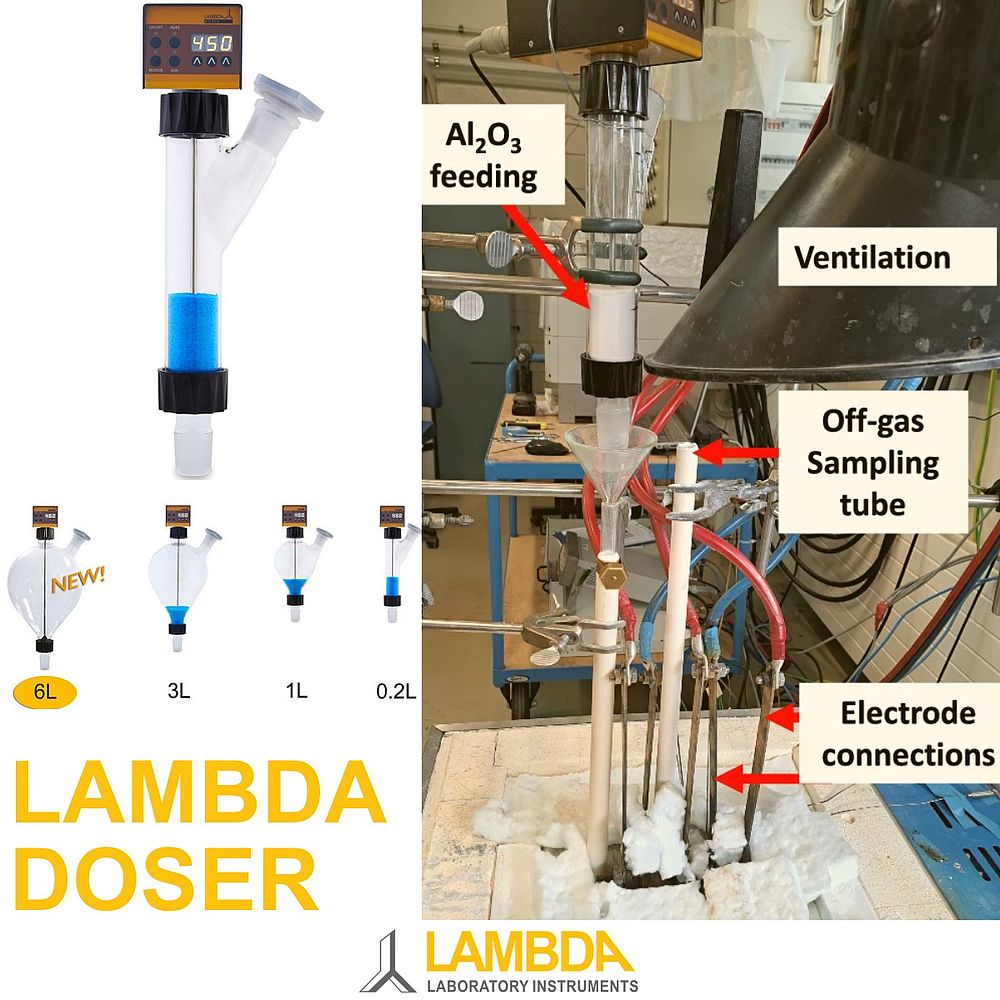

Integration of the LAMBDA DOSER to the Electrolysis Cell

The 0.2L POWDER DOSER was connected to alumina feed tubes passing through a ceramic reactor lid. The ceramic lid, with a thickness of 20 mm, was specially designed to accommodate the inert electrodes and included dedicated openings for off-gas measurement instruments as well as for the alumina and electrolyte feeders .

Fig 2: Integration of the LAMBDA DOSER 0.2L on the Electrolysis Cell (Reference: Senanu, S., Gunnarsson, G., Gunnarsson, D. et al. Characterization of Off-Gases from an Inert Electrode Aluminum Electrolysis Cell. J. Sustain. Metall. (2025). doi.org/10.1007/s40831-025-01348-0)

This design allowed simultaneous operation of the electrochemical cell, controlled powder feeding, and continuous gas analysis without disturbing the thermal or electrochemical stability of the system.

The LAMBDA POWDER DOSER delivered alumina directly into the molten electrolyte through the alumina feed tubes, ensuring controlled and reproducible material addition into the active reaction zone.

Feeding Method and Process Control

Smelter-grade alumina was dried prior to use and loaded into the LAMBDA POWDER DOSER. During electrolysis, the feeding rate was adjusted to correspond to approximately 80 % current efficiency, based on the applied current and expected alumina consumption

In addition to alumina, aluminum fluoride (AlF₃) was fed together with the alumina to counteract electrolyte evaporation and composition drift at elevated temperature. The ability to regulate the powder feed rate allowed the researchers to fine-tune alumina addition and avoid excessive concentration fluctuations in the electrolyte.

Early trials demonstrated that improper alumina feeding could lead to temporary increases in cell voltage. Based on this experience, the alumina feeder setup was optimized, resulting in significantly more stable voltage behavior during the later experiments.

Contribution to Stable Cell Operation

The use of the LAMBDA POWDER DOSER contributed directly to:

-

stable long-duration electrolysis runs,

-

controlled electrolyte chemistry,

-

avoidance of alumina starvation or overfeeding,

-

and reproducible off-gas measurements.

Stable alumina feeding was essential for the reliable characterization of off-gases using gas chromatography, FTIR, and tunable diode laser spectroscopy. Variations in feeding rate were reflected in measurable changes in cell voltage, confirming the importance of precise powder dosing in this type of experimental setup.

Practical Relevance

This work demonstrates that the LAMBDA DOSER is suitable for use as a laboratory-scale alumina feeder in high-temperature electrochemical processes. Its application in an inert-electrode aluminum electrolysis cell shows that it can be reliably integrated into complex experimental systems where precise material addition is required under demanding conditions.

The results presented in the publication provide a documented example of the DOSER’s use in metallurgical and electrochemical research environments, supporting its applicability beyond conventional laboratory dosing tasks.

What Makes the LAMBDA POWDER DOSER Unique

The LAMBDA DOSER is built around quartz-controlled electronics that regulate the drive motor with very high precision—similar in principle to the technology used in high-accuracy electronic watches. Its open-spiral powder distributor is designed to prevent powder compaction and bridging, guiding material smoothly toward the center and ensuring stable, reproducible dosing.

Optimized for use in reactors, explosive proof box etc., the LAMBDA DOSER automates powder dispensing tasks that are otherwise slow and operator-dependent when performed manually.

The DOSER offers a wide and finely adjustable dosing range. For example, under standard laboratory conditions, sodium chloride can be dispensed from approximately 10 mg/min up to 250 g/min, making the system suitable for both small-scale research and routine laboratory applications.

Interchangeable vessels are available in 0.2 L, 1 L, 3 L, and 6 L volumes. Optional protective coatings can be applied to enhance safety and durability during handling and operation.

For more information about the LAMBDA DOSER, please visit www.lambda-instruments.com/powder-doser or contact us at sales@lambda-instruments.com for inquiries and quotations.