Use of the LAMBDA DOSER as a Dust Feeder

The LAMBDA DOSER is a precision powder dosing system designed to deliver dry, free-flowing solids in a highly controlled and reproducible manner. When configured as a dust feeder, it enables the generation of fine particle streams for applications in aerosol generation, pyrolysis, combustion studies, and real-time particle diagnostics such as LIBS (Laser-Induced Breakdown Spectroscopy) and LII (Laser-Induced Incandescence).

Principle of Operation:

The LAMBDA powder dosing instrument is a unique programmable pump for free-flowing solid substances. It allows the automatic or continuous addition of powders, powdery and crystalline materials.

The motor of the driving unit is controlled with quartz-driven electronics, similarly, as it is done in electronic watches. The powder distributor is of an open spiral type (not a screw type as is sometimes used in other systems and can lead to the compacting and blocking of the dosing screw). This spiral takes the powder and pushes it to the centre where it falls out of the dosing unit. The rotation speed of the dosing screw is electronically controlled, allowing precise adjustment of the powder feed rate. Depending on the physical properties of the material and the configuration used, the DOSER can deliver powders at rates ranging from a few milligrams per minute up to several grams per minute.

Dust Feeding Configuration

To function as a dust feeder, the LAMBDA DOSER is typically integrated into a T-junction or venturi-style gas inlet, where a stream of carrier gas (such as compressed air or nitrogen) entrains the dispensed powder. This setup creates a well-defined aerosol flow suitable for in-flight particle analysis or for introduction into high-temperature zones such as pyrolysis reactors.

The generated dust stream can be directed into vertical tubes, laser interaction chambers, or optical diagnostics systems. For recirculating setups, the system may include a cyclone separator to recover and recycle the particles, forming a closed-loop feeding system.

Applications

The LAMBDA DOSER has been successfully used as a dust feeder in various scientific studies and industrial simulations. Notable examples include:

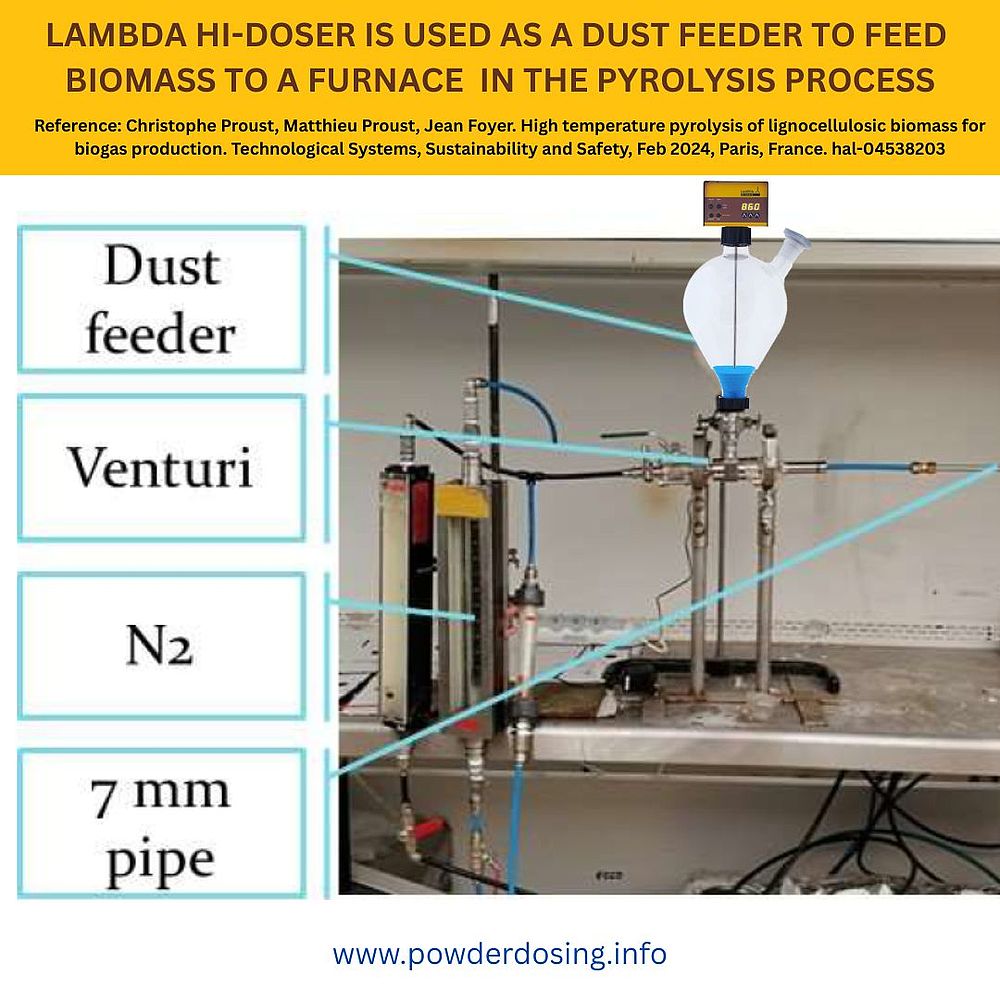

Biomass pyrolysis: Feeding powdered lignocellulosic material into a high-temperature reactor under inert gas flow (Proust et al., 2024).

Reference: Christophe Proust, Matthieu Proust, Jean Foyer. High temperature pyrolysis of lignocellulosic biomass for biogas production. Technological Systems, Sustainability and Safety, Feb 2024, Paris, France. hal-04538203

In this study, the HI-DOSER was used to continuously feed powdered biomass such as cellulose and lignin into a tubular furnace under nitrogen flow. The objective was to simulate flash pyrolysis conditions (heating rates >1000 °C/s) and analyze syngas production.

Role of the LAMBDA HI-DOSER:

- Fed biomass powder (1–20 g/min) into a nitrogen stream.

- Delivered powder uniformly into a high-temperature furnace.

- Enabled reproducible particle injection critical for accurate gas yield measurement.

Outcome:

The consistent and programmable powder flow allowed for precise analysis of heating rate effects on syngas yields. This led to quantifiable outputs (e.g., 1.1 Nm³/kg of syngas from cellulose at 1000 °C) and meaningful insights into the thermal degradation pathways of different biomasses.

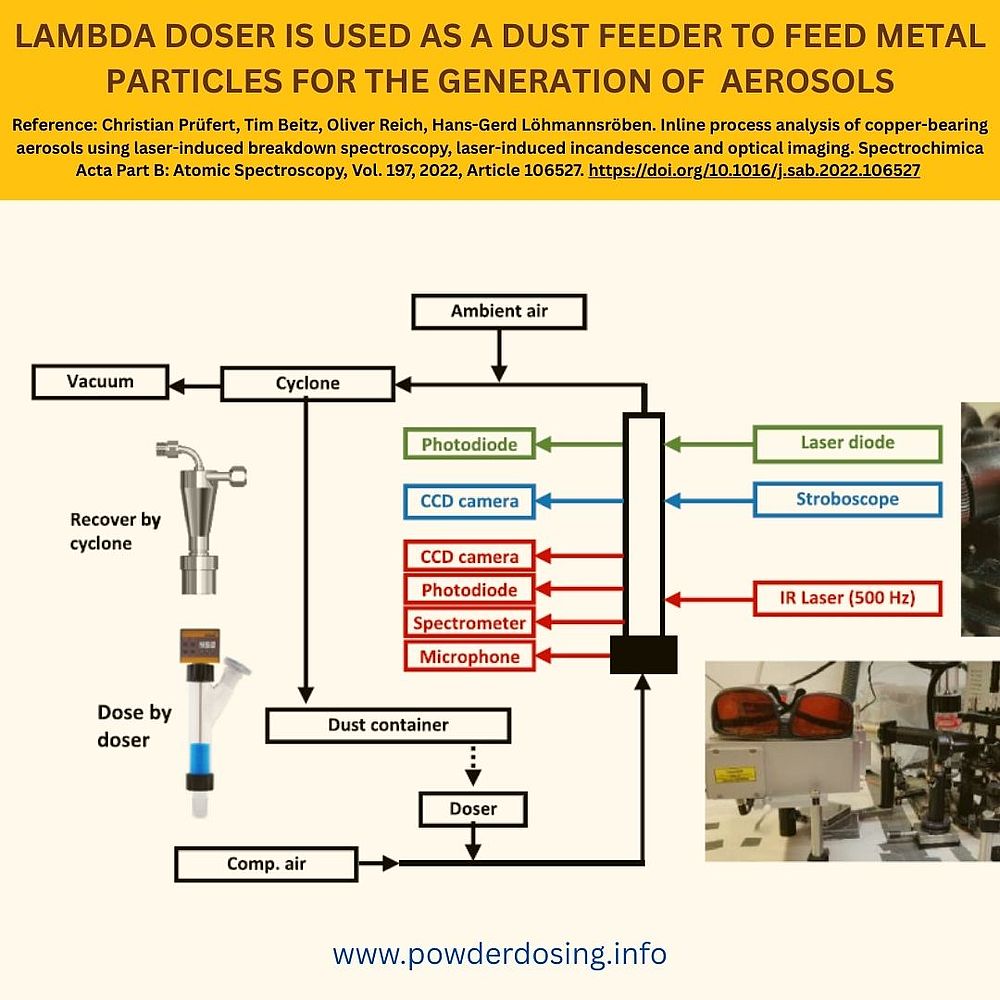

Aerosol diagnostics: Delivering calibrated dust streams for LIBS and LII studies of metal-bearing aerosols (Prüfert et al., 2022).

Reference: Christian Prüfert, Tim Beitz, Oliver Reich, Hans-Gerd Löhmannsröben. Inline process analysis of copper-bearing aerosols using laser-induced breakdown spectroscopy, laser-induced incandescence and optical imaging. Spectrochimica Acta Part B: Atomic Spectroscopy, Vol. 197, 2022, Article 106527. doi.org/10.1016/j.sab.2022.106527

In this study, the DOSER 0.2 L model was integrated into a closed-loop aerosol generation system designed for real-time, contactless analysis of aerosols using laser-induced breakdown spectroscopy (LIBS), laser-induced incandescence (LII), and stroboscopic imaging.

Role of the LAMBDA DOSER:

- Delivered controlled amounts of various metal particles includes Al₂O₃ and CuFeS₂ powders into an air stream.

- Enabled continuous aerosol generation with high particle concentration stability.

- Supported inline monitoring in a vertical quartz tube setup with optical detectors.

The DOSER enabled stable aerosol flow necessary for real-time classification and counting of individual particles based on their incandescence and spectral signatures. This was crucial for achieving high-resolution data (up to 500 Hz laser repetition) and for demonstrating LII as a viable method for aerosol classification.

Advantages in Dust Feeding Applications

- Precision and Stability: Offers consistent dosing, essential for experiments requiring reproducible particle number density or mass flow.

- Dust-Tight Design: Ensures safe and clean operation, minimizing contamination and particle losses.

- Flexible Integration: Can be easily coupled with analytical instruments, reactors, and aerosol generators.

- No Pneumatic Vibration Required: Unlike fluidized bed feeders, the LAMBDA DOSER operates without mechanical agitation, reducing system complexity and wear.

In both cases, the LAMBDA DOSER enabled controlled, real-time delivery of particulate material, ensuring experimental consistency and data quality.

Conclusion

When precise, reliable, and contamination-free powder delivery is required, the LAMBDA DOSER offers a robust solution. Its ability to function as a dust feeder makes it ideal for modern research involving aerosols, pyrolysis, combustion, and real-time particle analysis.