LAMBDA MINIFOR bioreactor enables precise control and monitoring of traditional co-culture fermentations

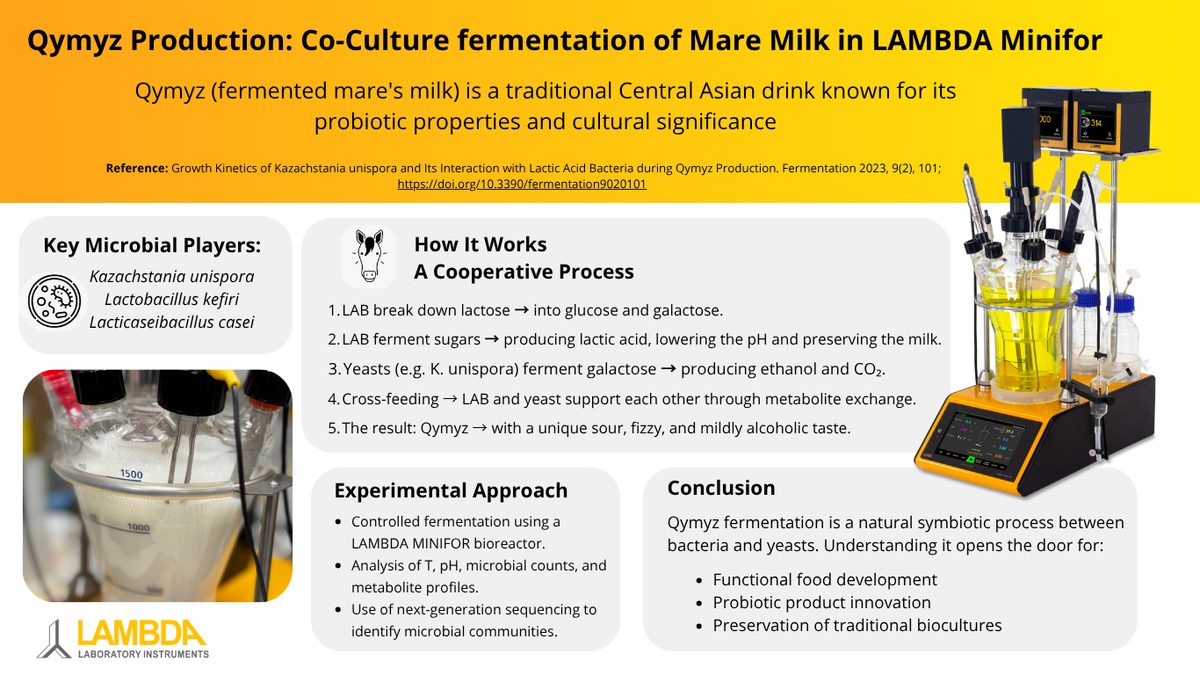

Qymyz (koumiss) is a traditional Central Asian fermented drink made from raw mare’s milk, valued for its probiotics and mild alcohol content. It’s typically made through spontaneous fermentation using lactic acid bacteria (LAB) and yeasts, but its quality varies due to unpasteurized milk and diverse local microflora.

To improve consistency, researchers from Kazakhstan and France used predictive microbiology to study microbial interactions using the laboratory fermenter and bioreactor LAMBDA MINIFOR, focusing on how the yeast Kazachstania unispora behaves alongside LAB in different conditions.

Why Study Qymyz Fermentation using LAMBDA MINIFOR fermenter and bioreactor?

Understanding the microbial interactions in Qymyz fermentation can help:

- Optimize production processes

- Improve consistency and safety

- Enhance probiotic potential for modern functional foods

However, co-culture systems are complex and require precise environmental control to accurately study microbial dynamics — making the LAMBDA MINIFOR bioreactor an ideal research tool.

Key Microbial Players in Qymyz Fermentation

The study focused on:

- Lactic Acid Bacteria (LAB) such as Lactobacillus casei and Lactobacillus kefiri, which are responsible for lactose fermentation and acidification.

- Yeasts, especially Kazachstania unispora (formerly Saccharomyces unisporus), which play a crucial role in producing alcohol, aroma compounds, and CO₂.

These organisms were grown together in mare’s milk under tightly regulated LAMBDA MINIFOR bioreactor conditions to investigate their behavior across different fermentation settings.

How the LAMBDA MINIFOR Enabled Precision Fermentation

In this study, researchers used the LAMBDA MINIFOR fermenter with a working volume of 800 mL to conduct controlled growth and co-culture experiments. Key operational highlights include:

>>> Growth Experiments – Effect of Temperature

- Conducted in MINIFOR bioreactor using an infrared radiator for temperature control.

- Yeast was cultured at 11 different temperatures, ranging from 5 °C to 40 °C, to determine its tolerance and optimal conditions.

- pH was automatically maintained at 5.6 using sterile 2 M NaOH.

- Agitation was kept constant at 240 rpm, ensuring homogeneous mixing.

These temperature-response experiments were crucial in identifying optimal growth conditions and stress thresholds for Qymyz-relevant yeast strains.

>>> Co-Culture Fermentation Experiments

Co-cultures were grown in LAMBDA MINIFOR under two specific conditions:

- L. casei – K. unispora at 25 °C

- L. kefiri – K. unispora at 30 °C

The MINIFOR’s precise temperature regulation and automated pH control allowed researchers to closely monitor co-culture dynamics, acidification rates, and microbial stability.

Reference: Growth Kinetics of Kazachstania unispora and Its Interaction with Lactic Acid Bacteria during Qymyz Production. Fermentation 2023, 9, 101. https://doi.org/10.3390/fermentation9020101

Use of Reconstituted Mare Milk and In-Situ Pasteurization

To further validate the findings, co-culture experiments were also repeated using reconstituted mare milk.

Prior to inoculation, the reconstituted milk was pasteurized directly in the LAMBDA MINIFOR bioreactor at 70 °C for 30 minutes, demonstrating the system’s flexibility not only for fermentation but also for media preparation and thermal processing.

Conclusion: Bridging Tradition with Technology

By combining traditional Qymyz fermentation with modern bioreactor control, this study illustrates how the LAMBDA MINIFOR bioreactor enables new insights into complex microbial ecosystems. Its flexibility, reliability, and ease of use make it an ideal tool for food microbiology and fermentation research. Researchers were able to:

- Identify optimal temperature conditions for key strains

- Study acidification kinetics in co-culture systems

- Lay the groundwork for improved probiotic beverages

Whether you're exploring ancient fermentation practices or developing modern functional foods, the LAMBDA MINIFOR offers the precision and control you need.

Interested in integrating the MINIFOR fermenter into your laboratory?

Contact us for technical details, configuration options, or to arrange a Teams/Zoom meetings.

Email us: sales@lambda-instruments.com