In Vitro Flow System for Dental and Implant Biofilm Research

Dental and oral biofilms are a major cause of peri-implantitis, periodontitis, and implant-associated infections. In the oral cavity, biofilms develop under continuous salivary flow, mechanical shear, anaerobic conditions, and stable physiological temperature. Static culture methods do not reproduce these conditions and often generate immature biofilms.

The LAMBDA Minifor Bioreactor enables a dynamic in vitro oral biofilm model that closely mimics the oral environment, making it suitable for dental biofilm research, dental implant studies, and oral microbiology applications.

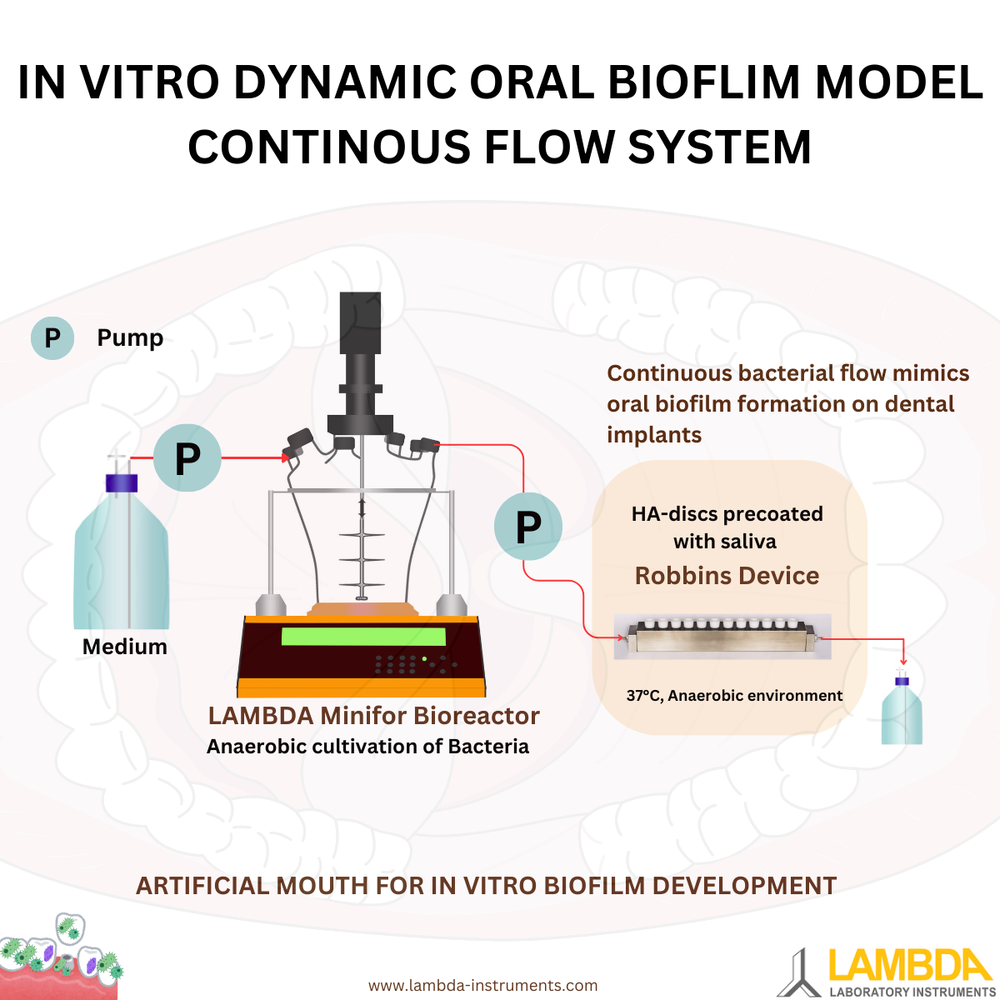

In Vitro Oral Biofilm Flow System Design

The LAMBDA Minifor Bioreactor acts as the central cultivation and conditioning unit. It maintains a homogeneous anaerobic bacterial culture at 37 °C, ensuring stable growth of single or multispecies oral microorganisms by automatic control of pH, gas supply and mixing.

Fig 1: Schematic overview of in vitro dynamic oral biofilm model flow system – LAMBDA Minifor Bioreactor with Robbins device

Using peristaltic pumps, the bacterial suspension is delivered in a laminar flow to a Robbins or modified Robbins device containing saliva-precoated hydroxyapatite discs or dental implants.

- Continuous bacterial culture flow to the implants by Peristaltic pump

- Laminar shear promotes realistic biofilm attachment

- Flow-through operation prevents metabolite accumulation

- Effluent is discarded (no recirculation)

This configuration supports the development of mature, structurally complex oral biofilms on implant surfaces.

Artificial Mouth Model for Dental Biofilm Research

The LAMBDA Minifor Bioreactor–Robbins device configuration functions as an artificial mouth model for in vitro biofilm development and is widely used for:

- Multispecies oral biofilm studies

- Dental implant and abutment surface evaluation

- Peri-implantitis and subgingival biofilm models

- Antimicrobial and antibiofilm efficacy testing

Biofilms generated using this system are suitable for downstream analysis using qPCR, confocal laser scanning microscopy (CLSM), and scanning electron microscopy (SEM).

Reference:

Use of the LAMBDA Minifor as an Artificial Mouth System for Oral Biofilm Growth

DENTAID Expertise. (2015).

Bioreactor system LAMBDA Minifor as an artificial mouth system for the growth of biofilms.

The Minifor was adapted as an artificial mouth model, enabling continuous nutrient flow and controlled conditions for dynamic oral biofilm growth.

Use of the LAMBDA Minifor in Antimicrobial Testing on Implant-Associated Oral Biofilms

The research was carried out by the Spanish research team led by A. Alonso-Español, together with E. Bravo, P. Nuevo, and colleagues, who are active in the field of oral biofilm research and dental implant microbiology.

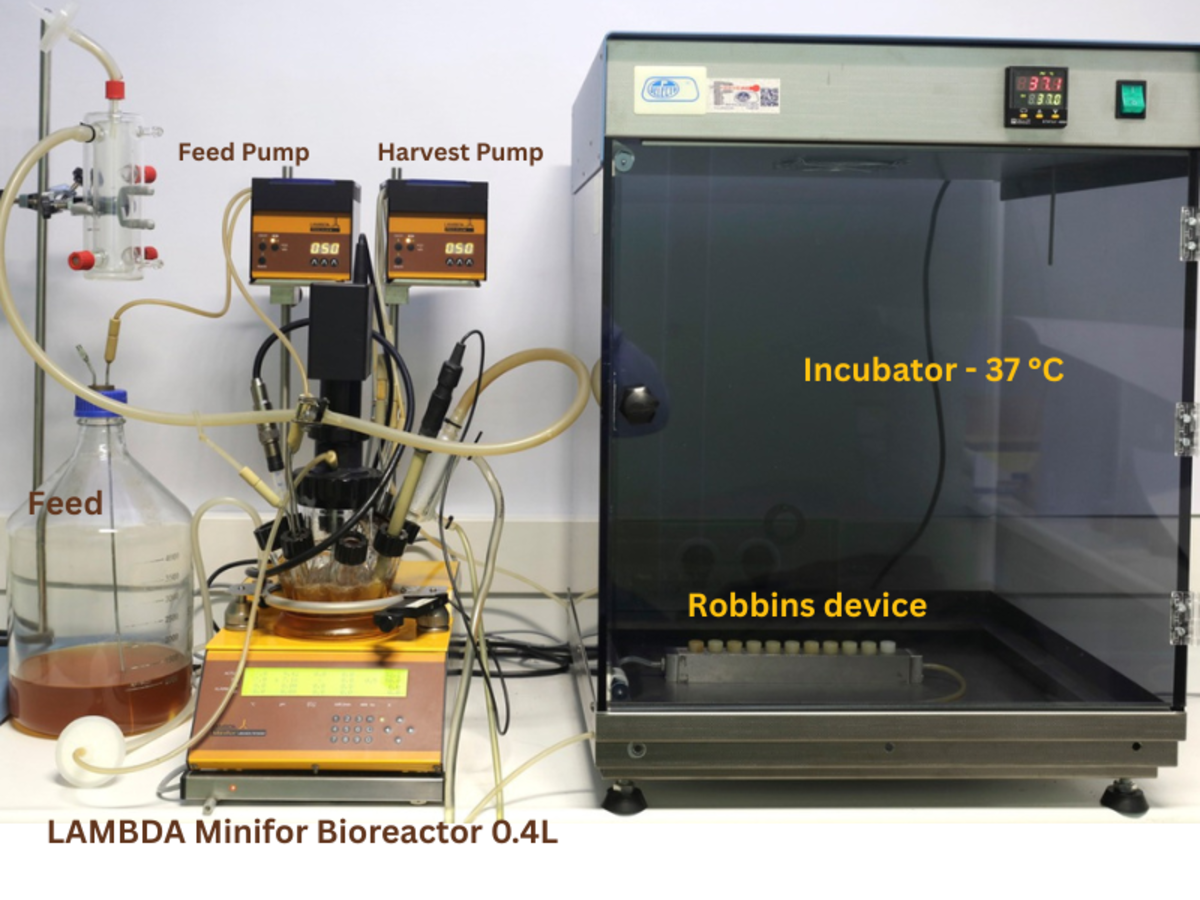

In this work, the LAMBDA Minifor bioreactor was used as a dynamic oral biofilm model to cultivate mature multispecies bacterial biofilms on dental implant surfaces under controlled flow conditions. The system provided continuous nutrient supply, physiological temperature control, and defined hydrodynamic forces, enabling biofilms to develop with a structure and resistance comparable to clinical implant-associated biofilms.

Fig 2: LAMBDA Minifor Bioreactor connected to the Robbins device (Reference: Alonso-Español, A.; Bravo, E.; Ribeiro-Vidal, H.; Virto, L.; Herrera, D.; Alonso, B.; Sanz, M. The Antimicrobial Activity of Curcumin and Xanthohumol on Bacterial Biofilms Developed over Dental Implant Surfaces. International Journal of Molecular Sciences, 2023, 24, 2335. DOI: https://doi.org/10.3390/ijms24032335)

After biofilm maturation, implant samples were exposed to curcumin and xanthohumol to evaluate their antimicrobial activity. Because the biofilms were grown under dynamic Minifor conditions, the antimicrobial effects reflected performance against clinically relevant, well-established oral biofilms, rather than immature static cultures.

Interchangeable vessels with working volume from 35ml - 6L

Fig 3: The LAMBDA Minifor2Bio touch 0.4L Advanced kit

Other Short Selected References of the LAMBDA Minifor Bioreactor in Oral and Dental Research

Use of the LAMBDA Minifor to Assess the Effect of Implant Surface Chemistry on Oral Biofilm Formation

Nuevo, P., Bravo, E., Alonso-Español, A., Ribeiro-Vidal, H., Herrera, D., & Sanz, M. (2025).

In vitro assessment of a novel piranha-passivated dental implant surface against oral biofilm formation.

Clinical Oral Implants Research.

https://doi.org/10.1111/clr.70031

Evaluation of Implant Decontamination Methods under Dynamic Biofilm Conditions using of the LAMBDA Minifor Bioreactor

Khan, S. N., Bravo, E., Nuevo, P., Herrera, D., & Sanz, M. (2025).

The decontamination effect of an oscillating chitosan brush compared with an ultrasonic PEEK-tip: An in vitro study using a dynamic biofilm model.

Clinical Oral Implants Research, 36(1), 73–81.

https://doi.org/10.1111/clr.14360

Use of the LAMBDA Minifor to Study Bacterial–Fungal Interactions in Subgingival Biofilms

Bravo, E., Alonso-Español, A., Nuevo, P., Ribeiro-Vidal, H., Herrera, D., & Sanz, M. (2024).

Impact of Candida albicans on multispecies subgingival biofilm development on dental implant surfaces.

International Journal of Molecular Sciences, 25, 3277.

https://doi.org/10.3390/ijms25063277

Use of the LAMBDA Minifor for Antimicrobial Testing on Mature Implant-Associated Oral Biofilms

Alonso-Español, A., Bravo, E., Ribeiro-Vidal, H., Virto, L., Herrera, D., Alonso, B., & Sanz, M. (2023).

The antimicrobial activity of curcumin and xanthohumol on bacterial biofilms developed over dental implant surfaces.

International Journal of Molecular Sciences, 24, 2335.

https://doi.org/10.3390/ijms24032335

Use of the LAMBDA Minifor for Multispecies Oral Biofilm Formation on Dental Implant Surfaces

Bravo, E., López-Píriz, R., Valderrama, P., Wilson, T. G., & Herrera, D. (2023).

Biofilm formation on dental implants with a hybrid surface microtopography: An in vitro study in a validated multispecies dynamic biofilm model.

Clinical Oral Implants Research, 34(5).

https://doi.org/10.1111/clr.14054

Use of the LAMBDA Minifor in Dynamic In Vitro Models for Caries-Related Dental Biofilms

Salli, K. M., & Ouwehand, A. C. (2015).

Use of in vitro model systems to study dental biofilms associated with caries: A short review.

Journal of Oral Microbiology, 7, 26149.

https://doi.org/10.3402/jom.v7.26149

Summary

When combined with a Robbins or modified Robbins device, the LAMBDA Minifor bioreactor functions as the backbone of a validated dynamic oral biofilm model. Its role is essential for reproducing oral environmental conditions, enabling mature biofilm formation on dental implants, and supporting high-quality antimicrobial and pathogenesis research.

The successful use of this configuration in multiple peer-reviewed studies confirms its value for oral microbiology, peri-implantitis research, and implant surface evaluation under clinically relevant in vitro conditions.

Ready to elevate your research? Explore the LAMBDA Minifor2Bio touch Fermenter-Bioreactor today and discover how it can transform your work. You can read more at the product page - www.lambda-instruments.com/fermenter-bioreactor-touch/

NEW! - The new Minifor2Bio touch laboratory fermenters-bioreactors are now available!

Read more: https://fermenters.eu/

If you have any inquiries, require a quotation, or need pricing information for our fermentor-bioreactor system, feel free to reach out to us at sales@lambda-instruments.com.