2 PROGRAMMING OF THE POWDER DOSER / HI-DOSER

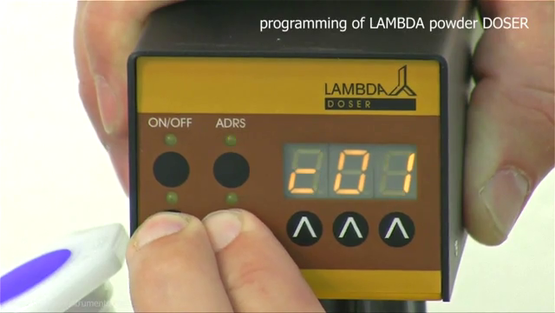

Up to 27 pairs of speed and time settings (flow rates) can be programmed in DOSER and up to 99 steps of speed and time can be programmed in HI-DOSER.

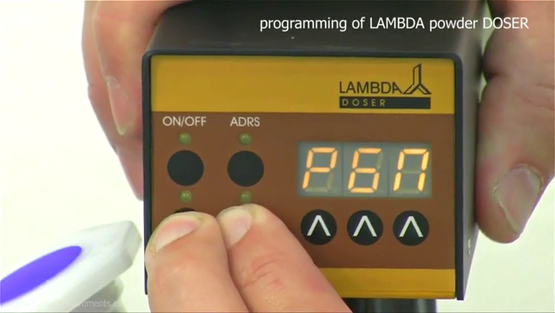

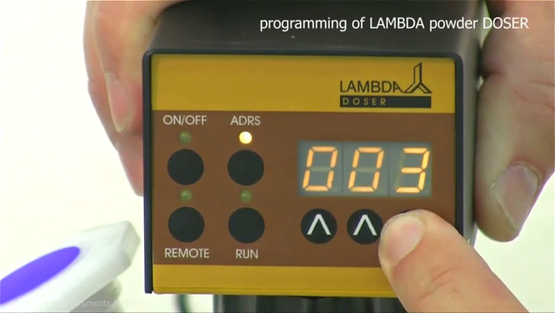

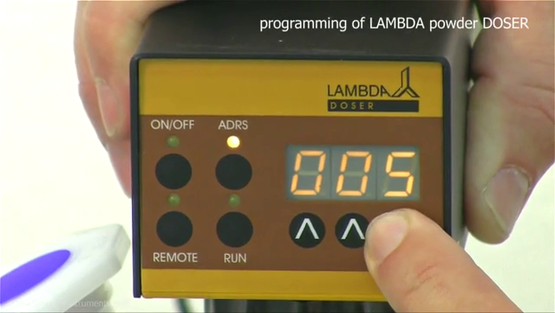

The programming mode is accessed by simultaneously pressing the buttons REMOTE and RUN until the indication “PGM” appears on display and the REMOTE and RUN LEDs are switched on.

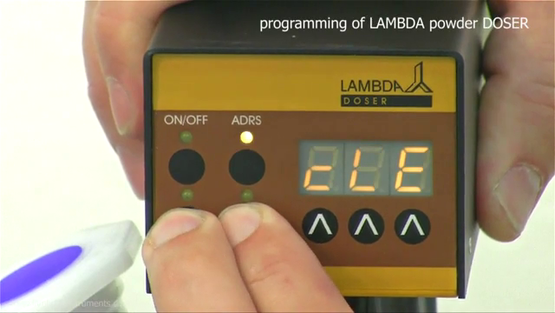

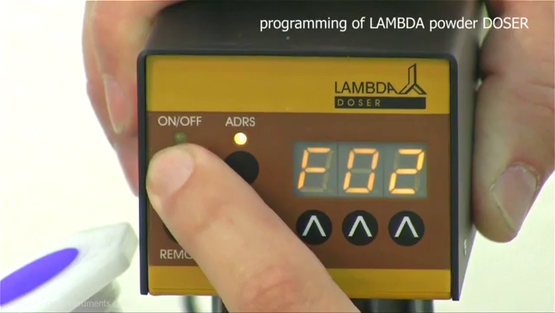

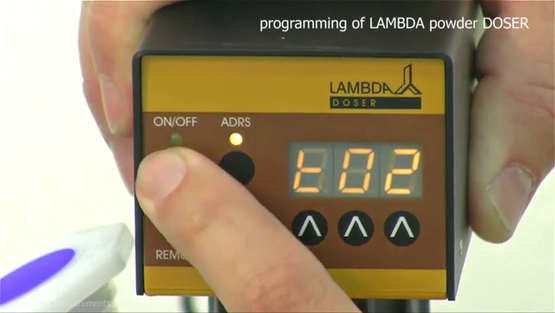

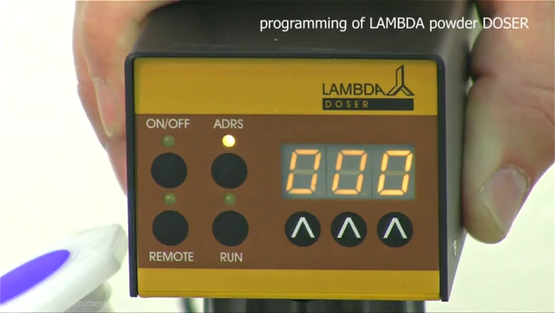

Remark: If you repeat the following simultaneous pressing of the REMOTE and RUN buttons, the memory will be cleared and the indication “cLE” will appear on the display (Figure 2-2). To enter the programming mode again, press the REMOTE and RUN buttons again until “PGM” appears (Figure 2-1).

.

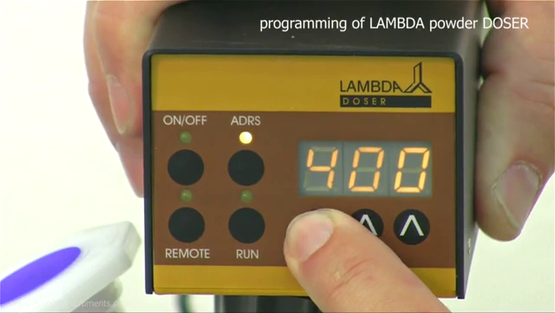

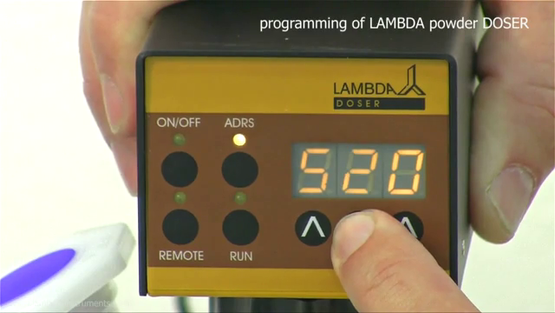

In a similar way up, to 27 program steps can be entered in DOSER and up to 99 program steps can be entered in HI-DOSER.

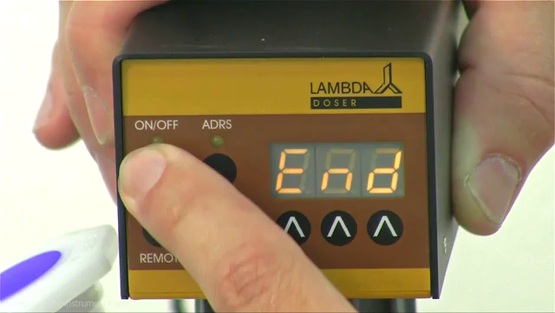

Remark: It is not possible to end the program after programming the time data.

.

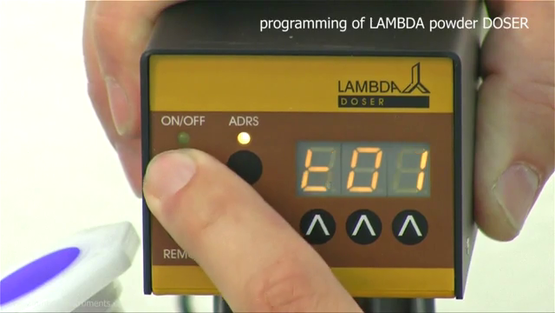

To stop the running program definitively, press the RUN button. The RUN and ON/OFF LEDs are switched OFF.

It is possible to stop the pump by pressing the ON/OFF button, to change the rotation speed during any running program step. This allows the reaction in emergency situations.

Remark: Do not forget to switch ON the powder DOSER or HI-DOSER again (by pressing the ON/OFF button), after finishing the intervention.