LAMBDA MINIFOR laboratory fermenter and bench-top bioreactor at universities and technical schools

Why is the LAMBDA MINIFOR laboratory fermenter and benchtop bioreactor so attractive to universities and high schools?

It’s not only because of its functionality and accuracy…

1. Modular lab fermenter

“Your MINIFOR adapts to your project goals – not vice versa!”

If your project changes you can add additional modules at any time (other vessel sizes, pumps, integrators, mass flow gas controllers, software…).

Is your new project less complex? Then, use the surplus modules as autonomous or stand-alone devices in your lab. (Peristaltic pumps, mass flow gas flow controllers, …)

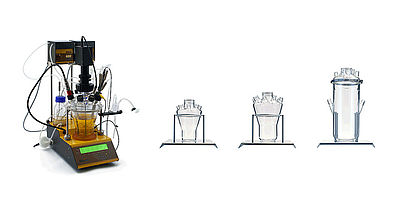

2. Interchange reactor volumes at low cost

“In addition to the standard 1L vessel we can also supply 0.3L (with a minimal working volume of 35ml), 0.4L, 3L and 7L reactor vessels. The vessels can be replaced easily and at low cost. What else can we do for you?”

This is only one example of the modularity of the fermenter system.

Each MINIFOR unit has its own measurement and control electronics for all parameters (pH, pO2, temperature, agitation, aeration rate and one additional selectable parameter). You can decide which parameters and accessories are needed for your work. This allows low acquisition costs.

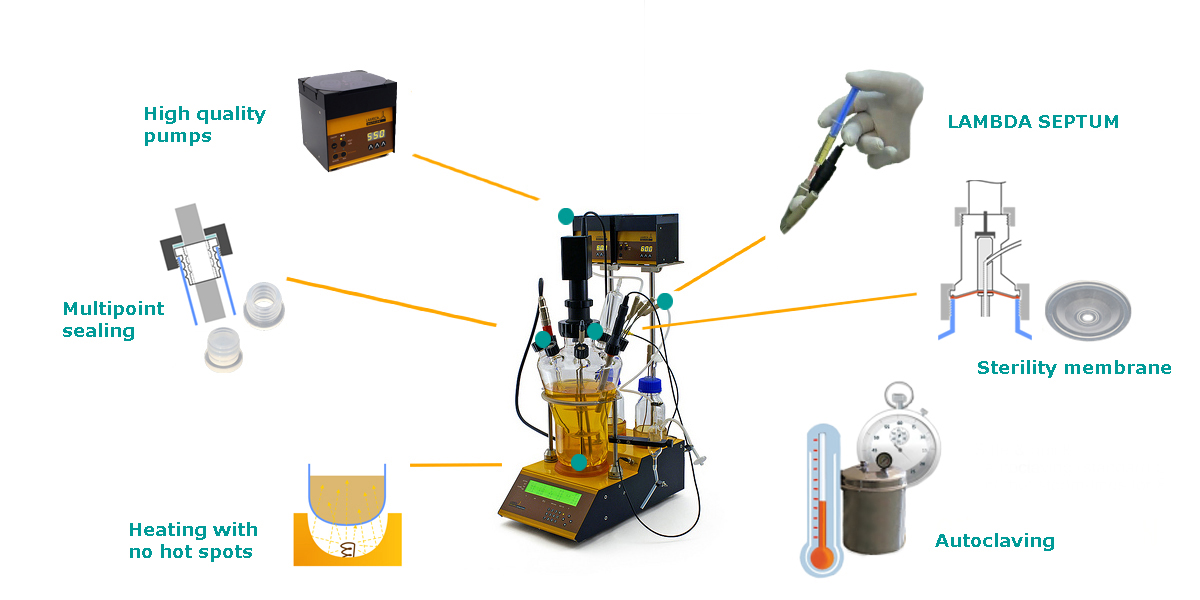

3. Safe and easy handling in practical lessons

“Don’t be afraid of sterilization ...”

No additional safety measures are required as in the case of “in-place” sterilization (SIP): The MINIFOR fermenter-bioreactor can be sterilized in common autoclaves in the laboratory.

4. Compact lab fermenter-bioreactor

“Watch your MINIFOR, because your handy laboratory fermenter-bioreactor can be carried away by a single person!"

The MINIFOR laboratory bioreactor unit requires the surface of approximately an A4 sheet of paper.

The MINIFOR requires very little bench space and all ports are easily accessible: The side necks for the probes and connections are positioned at an angle of 30°. The space gained in this way allows for simple sterile work.

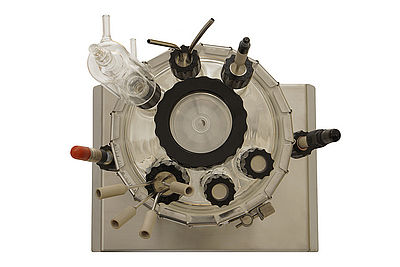

5. Low maintenance costs

“MINIFOR runs without the need of frequently replacing consumables.”

Instead of O-rings or other seals which have to be replaced frequently, MINIFOR uses heavy-duty silicone membranes and multipoint seals.

The peristaltic pumps perfectly work with even lowest cost silicone tubing without excessive wear out. This ensures accurate liquid dosage in long-term continuous processes.

The special concept of the MINIFOR fermenter-bioreactor offers lowest maintenance costs and short dead times for installation and dismantling between experiments.

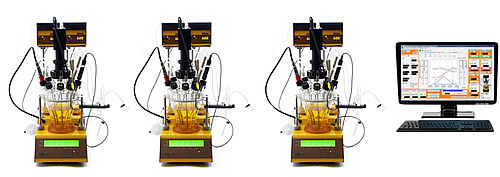

6. Team member in parallel runs

“MINIFOR is not only a loner. It is also a great team player in parallel processes – without losing its independence.”

Unlike conventional systems, the MINIFOR units do not need to be placed next to each other during parallel processes, but can be distributed across your labs. Each MINIFOR unit has its own console which regulates all parameters locally and shows at one single glance the actual and set values as well as high and low alarms of each parameter.

Several MINIFOR units can be connected to you PC and the optional software allows remote control and data processing.

For connecting multiple MINIFOR fermenter-bioreactor units to the PC no additional software licenses are necessary.