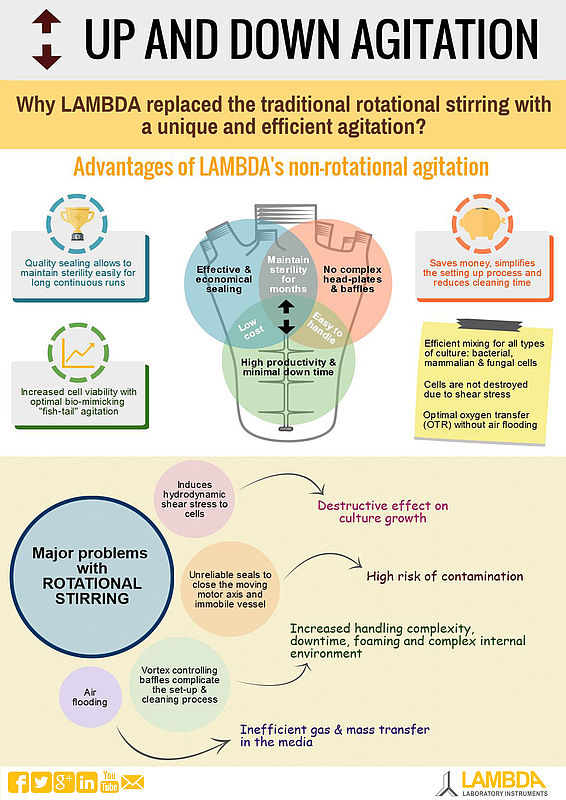

Why LAMBDA replaced the traditional rotational stirring with a unique and efficient agitation?

Almost all laboratory fermenters-bioreactors use circular rotation to agitate the culture medium. The rotational stirring has its own disadvantages.

Major problems with rotational stirring

- Induces hydrodynamic shear stress - Destructive effect on culture growth

- Unreliable seals to close the moving motor axis and immobile vessel - High risk of contamination

- Vortex controlling baffles complicate the setup and cleaning process - Increased handling complexity, downtime, foaming and complex internal environment

- Air flooding - Inefficient gas and mass transfer in the media

| LAMBDA has found a very simple, innovative solution for the conventional mixing problems. Advantages of LAMBDA’s non-rotational agitationQuality sealing allows to maintain sterility easily for long continuous runs

Efficient mixing for all types of culture: bacterial, mammalian and fungal cells. Cells are not destroyed due to shear stress. Optimal oxygen transfer (OTR) without air flooding. |