Biosurfactants (microbial-produced surfactants) are a promising alternative for chemically-synthesized surfactants in industrial applications. They are more effective, selective, environmentally friendly, and stable than many synthetic surfactants. To produce a large quantity of biosurfactant rhamnolipid (RL), researchers from the Baghdad University used wild strains of Pseudomonas aeruginosa isolated from the local region of Iran.

P. aeruginosa was producing rhamnolipid in LAMBDA MINIFOR 7L fermentor

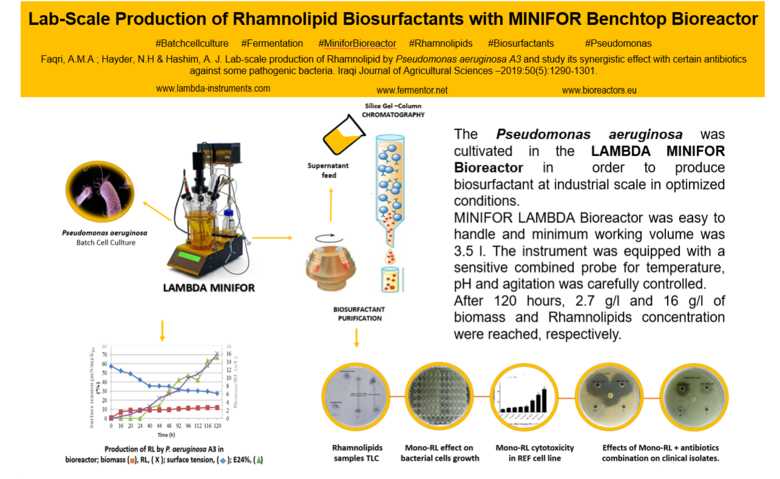

Isolated strains of Pseudomonas aeruginosa were cultivated in the batch mode using LAMBDA MINIFOR 7L fermentor for the production of biosurfactant rhamnolipid.

Reference: Faqri, A.M.A ; Hayder, N.H & Hashim, A. J. Lab-scale production of Rhamnolipid by Pseudomonas aeruginosa A3 and study its synergistic effect with certain antibiotics against some pathogenic bacteria. Iraqi Journal of Agricultural Sciences –2019:50(5):1290-1301. doi.org/10.13140/RG.2.2.10802.35520

After 120 h, the surface tension of the solution reached 27.2 mN/m, with 67% of emulsification activity and biomass 2.7 g/l. The RL concentration was 16 g/l. Using Silica-gel chromatography, Thin Layer Chromatography (TLC) and Fourier Transform Infrared Spectroscopy (FTIR) for spectral analysis, the biosurfactant mixture obtained was characterized mainly of both mono- and di-rhamnolipids. Cytotoxicity assays of mono-RL were done, obtaining a Minimum Inhibitory Concentration (MIC) of 250 µg/mL for most of bacterial used in the experiments, revealing a synergistic effect with antibiotics such as: ampicillin against Staphylococcus aureus and Serratia marcescens, with cefotaxime against Escherichia coli and Klebsiella pneumoniae, same as with tetracycline.

LAMBDA MINIFOR fermentor was easy to handle and all important cultural conditions could be measured and controlled.

Ergonomic and easy handling of the fermentor. Why?

Why is LAMBDA MINFOR fermentor ergonomic and easy to handle?

- Highly compact and elimination of casing tower with the use of microprocessors allowing to place all the electronics in the front part of the instrument.

- Despite its small size, six parameters are measured and controlled in the basic configuration of the MINIFOR.

- Smallest footprint even for parallel experiments. The space requirement of the MINIFOR fermentor-bioreactor with working vessel and the control unit is: 22 cm x 38 cm x 40 cm (W x H x D).

- Minimum space on the bench, but with good access to all parts.

- Can be fully controlled and operated from the front panel.

- All parameters can be immediately seen without scrolling and set values as well as high and low alarms of each parameter can be adjusted on the front panel.

- Several MINIFOR units can be connected to one PC and the optional fermentation PC-software SIAM or FNet, allows remote control and data processing.

Features of LAMBDA MINIFOR bench-top fermenter could be found at www.fermentador-bioreactor.com/features/ and www.lambda-instruments.com/fermenter-bioreactor/

Keywords: Batch fermentation, LAMBDA MINIFOR, fermentor, biosurfactants, rhamnolipids, cytotoxicity, antibiotic synergy, MIC, minimum inhibitory concentration, Pseudomonas.