Mouse hybridoma cell culture in LAMBDA MINIFOR benchtop bioreactor

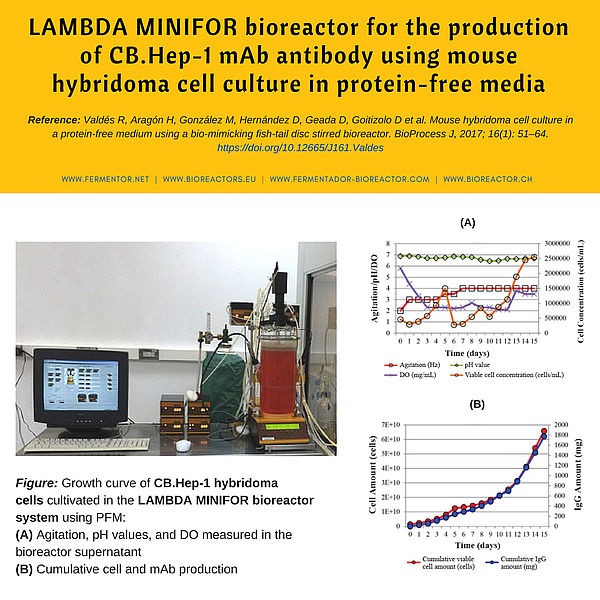

In the recent study by CIGB Cuba, LAMBDA MINIFOR lab-scale bioreactor used to cultivate mouse hybridoma cells in protein-free medium (PFM) for the antibody production under fed-batch and continuous mode of operation.

Figure 1: Reference Valdés R, Aragón H, González M, Hernández D, Geada D, Goitizolo D et al. Mouse hybridoma cell culture in a protein-free medium using a bio-mimicking fish-tail disc stirred bioreactor. BioProcess J, 2017; 16(1): 51–64. doi.org/10.12665/J161.Valdes

The LAMBDA MINIFOR bioreactor with 7 L vessel volume (Figure 1) was inoculated with CB.Hep-1 hybridoma and all key parameters such as temperature, agitation, DO concentration and pH were automatically regulated by LAMBDA MINIFOR bioreactor and SIAM industrial fermentation software.

Results obtained in the study shows a cumulative CB.Hep-1 mAb production of 1.77 g over 15 days, achieve the highest cell concentration of 2.45 × 106 viable cells/mL, maximum cell viability of 86%, exponential growth rate of 0.0156/h and cell population doubling time of 44 h.

The purity of CB.Hep-1 mAb obtained from LAMBDA MINIFOR bioreactor supernatant assessed by SDS-PAGE analysis carried out under reducing conditions was 99.5%.

Automated gas mixing module with thermal LAMBDA MASSFLOW gas flow controllers for cell cultures

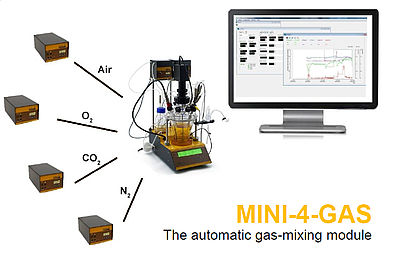

Figure 2: MINI-4-GAS automatic gas mixing module with massflow gas flow controllers for mammalian cell cultures

LAMBDA MINI-4-GAS gas-mixing module allows a customized thermal massflow controlled supply of different gases (air, O2, CO2, N2) with individual gas flow paths for mammalian cell cultures. It maintains the optimal physiologic conditions of mammalian and stem cell cultures using modern control strategies.

For example: MINI-4-GAS allows automatic control of pH of cell culture by controlled addition of gaseous CO2.

Bio-mimicking shear stress free ‘fish-tail’ agitation

Unique bio-mimicking "fish-tail" agitator provides efficient agitation without mechanical stress to cells:

- Gentle yet efficient mixing

- No hydrodynamic shear stress which increases cell viability (highly beneficial for stem cells, HeLa, HEK-293, CHO and other mammalian cell lines)

- Good oxygenation and suboptimal gas exchange in medium

The stirrer frequency can be adapted at any time and programmed from 0 to 20 Hz (which corresponds to 0 to 1200 rpm) in steps of 0.1 Hz (6 rpm).

The type and number of ‘fish-tail’ stirring discs can be adapted according to the cell lines and working volume. The “fish-tail” agitation discs are efficient even at very low volumes of medium in the vessel.

Aseptic handling of LAMBDA MINIFOR bioreactor in long continuous cell cultures

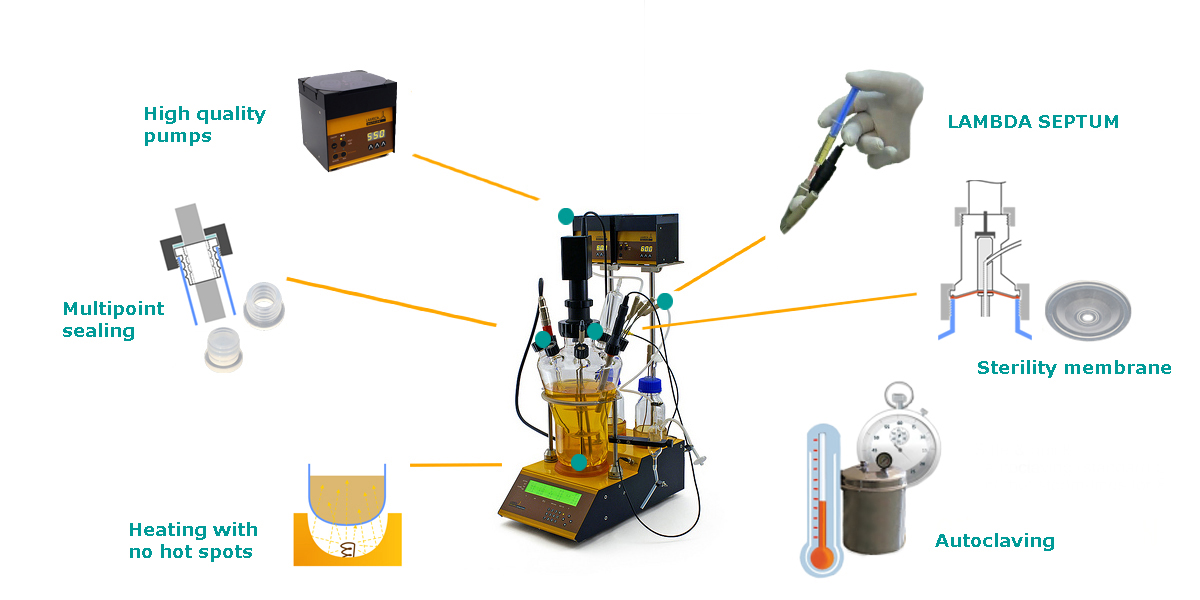

Unique construction of LAMBDA MINIFOR bioreactors helps to maintain sterility easily for batch, fed-batch and continuous cell culture processes.

Figure 3: Unique construction of LAMBDA MINIFOR bioreactor for easy sterility maintenance in long cell culture processes

Complete closure with permanent multipoint sealing for ports with probes, septum (for aseptic seeding), gas and liquid-lines on the bench-top bioreactor.

LAMBDA offers reliable peristaltic pumps for stable and reproducible flow rates without the risk of tubing rupture for several weeks.

Further features of LAMBDA MINIFOR lab scale bioreactor for cell culture could be found at www.fermentador-bioreactor.com/features/ and www.lambda-instruments.com/fermenter-bioreactor/.

Keywords: Hybridoma cell culture; Protein free medium (PFM); Monoclonal antibody production (mAb); LAMBDA MINIFOR bioreactor; Biomimicking fish-tail agitation; Cell viability; 4-gas mix