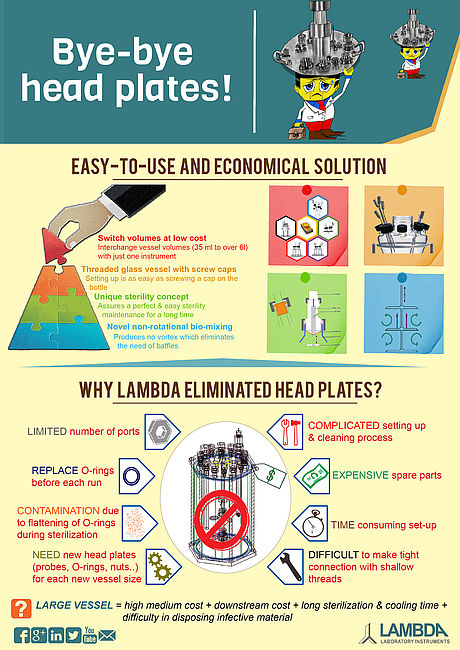

Elimination of expensive head plates in MINIFOR fermentor-bioreactor

Head plates are the most expensive part of the vessel and also the component which creates most problems. Head plates on low volume laboratory fermenters/bioreactors have been simply scaled down from larger fermentors.

To setup a fermentation vessel with head plates takes much time and each vessel size requires not only a new head plate but also longer pH and pO2 probes, antifoam and temperature probes and practically everything on the head (O-rings, nuts, lead-throughs,...). This is extremely expensive.

Therefore, very often researchers decide to buy the vessel of largest volume to spare investment money.

However, working with higher than needed volume is also very expensive.

Easy-to-use and economical solution

LAMBDA has decided to question the use of head plates and found a very practical, easy-to-use and economical solution instead.

- Switch volumes at low cost: Interchange vessel volumes (35 mL to over 6L) in just one instrument

- Threaded glass vessel with screw caps: Setting up is as easy as screwing a cap on the bottle

- Unique sterility concept: Assures a perfect & easy sterility maintenance for a long time

- Novel non-rotational bio-mixing: Produces no vortex which eliminates the need of baffles