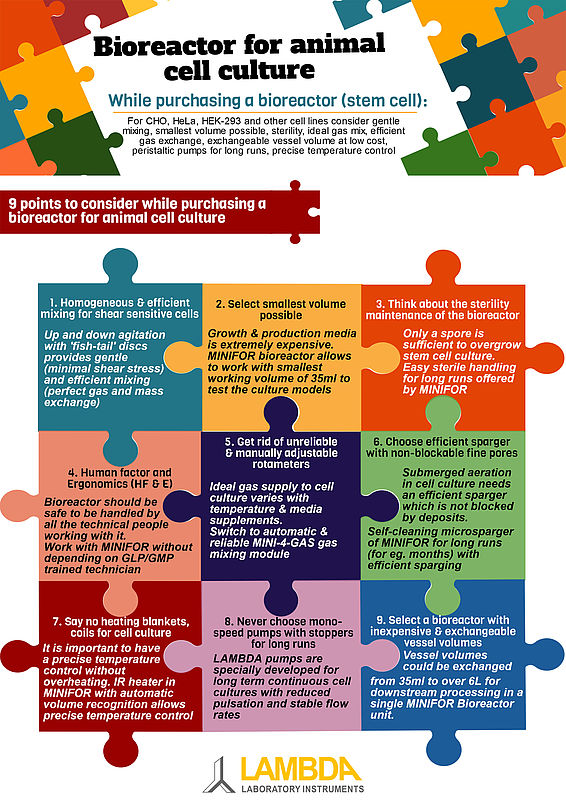

9 points to consider while purchasing a bioreactor for animal cell culture

While purchasing a bioreactor for CHO, HeLa, HEK-293 and other cell lines consider gentle mixing, smallest volume possible, sterility, ideal gas mix, efficient gas exchange, exchangeable vessel volume at low cost, peristaltic pumps for long runs and precise temperature control.

| 1. Homogeneous & efficient mixing for shear sensitive cellsUp and down agitation with 'fish-tail' discs provides gentle (minimal shear stress) and efficient mixing (perfect gas and mass exchange). 2. Select smallest volume possibleGrowth & production media is extremely expensive.MINIFOR bioreactor allows to work with smallest working volume of 35ml to test the culture models 3. Think about the sterility maintenance of the bioreactorOnly a spore is sufficient to overgrow stem cell culture.Easy sterile handling for long runs offered by MINIFOR bioreactor. 4. Human factor and Ergonomics (HF & E)Bioreactor should be safe to be handled by all the technical people working with it.Work with MINIFOR bioreactor without depending on GLP/GMP trained technician.

5. Get rid of unreliable & manually adjustable rotametersIdeal gas supply to cell culture varies with temperature & media supplements. |

6. Choose efficient sparger with non-blockable fine pores

Submerged aeration in cell culture needs an efficient sparger which is not blocked by deposits.

Self-cleaning microsparger of MINIFOR bioreactor for long runs (for e.g. months) with efficient sparging.

7. Say no heating blankets, coils for cell culture

It is important to have a precise temperature control without overheating.

IR heater in MINIFOR bioreactor with automatic volume recognition allows precise temperature control.

8. Never choose a mono-speed pumps with stoppers for long runs

LAMBDA peristaltic pumps are specially developed for long term continuous cell cultures with reduced pulsation and stable flow rates.

9. Select a bioreactor with inexpensive & exchangeable vessel volumes

Vessel volumes could be exchanged from 35 ml to over 6 L for downstream processing in a single MINIFOR bioreactor unit.