Pump-flow INTEGRATOR

Pump-flow INTEGRATOR

Pump-flow INTEGRATOR allows the electronic recording of the transferred amount of liquid/powder/gas as a function of time.

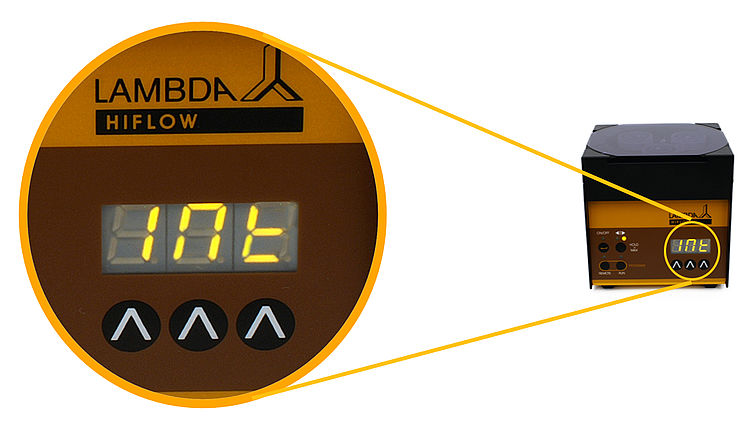

Integrated electronically within the LAMBDA Peristaltic Pump and other LAMBDA instruments (powder dosing instrument, MASSFLOW gas flow measurement unit, syringe pumps), the pump-flow integrator helps to record the amount liquid (or powder or gas) that has been pumped as a function of time.

When the pump is used for the regulation of reaction conditions such as pH, temperature or other parameters, it is important to know how much of the solution (acid or base, for example) has been added to maintain a constant pH. This additional data will inform you about the kinetics of the process, its completion or even disturbances that have occurred during the process.

Typical applications of the PUMP-FLOW INTEGRATOR:

- Control of pH during chemical reactions where the pH is controlled by the addition of acid or base (eg. hydrolysis of esters, amides, anhydrides etc.)

- Control and quantification of the metabolical activity of cells during fermentations and cell-cultures (eg. by control of pH, rH, pO2, pCO2, conductivity or other parameters)Measurement of the enzyme activity of numerous enzymes (eg. esterases, acylases, lipases, proteases and others using a pH stat)

- Recording foam formation (automatic addition of antifoam agent)

- Recording the addition of reactants during exothermic reactions where the addition of reactants are controlled by a thermostat

- Recording the consumption of reactants during titrations.

The principles of the PUMP-FLOW INTEGRATOR

The heart of LAMBDA Pumps (or LAMBDA DOSER) is a stepping motor (or BLDC motor) controlled by a generator of electrical impulses. After each impulse, the motor turns by one step. This movement is transmitted to the rotor, which displaces a small amount of liquid in the direction of flow by compression of the tubing. The pump-flow integrator registers impulses received and transforms them into a direct current. The voltage can be measured or recorded by common recorders or voltmeters.

By dividing off the step frequency, the sensitivity of integration can be varied in a ratio of 1 to 512. According to the diameter of the tubing and the sensitivity selected, it is possible to measure volumes between 2.0 to 4,000 ml. This allows the use of the integrator on an analytical and preparative scale.

The automatic reset function returns the integrator to zero after the full scale value has been attained. This allows the use of unlimited amounts of liquid.

The PUMP-FLOW INTEGRATORs are embedded electronically within the control unit of LAMBDA peristaltic pumps, powder feeder, syringe pumps and gas flow controllers.